Performance Characteristics of Polyurethane Fiberglass FRP Composite Pultrusion

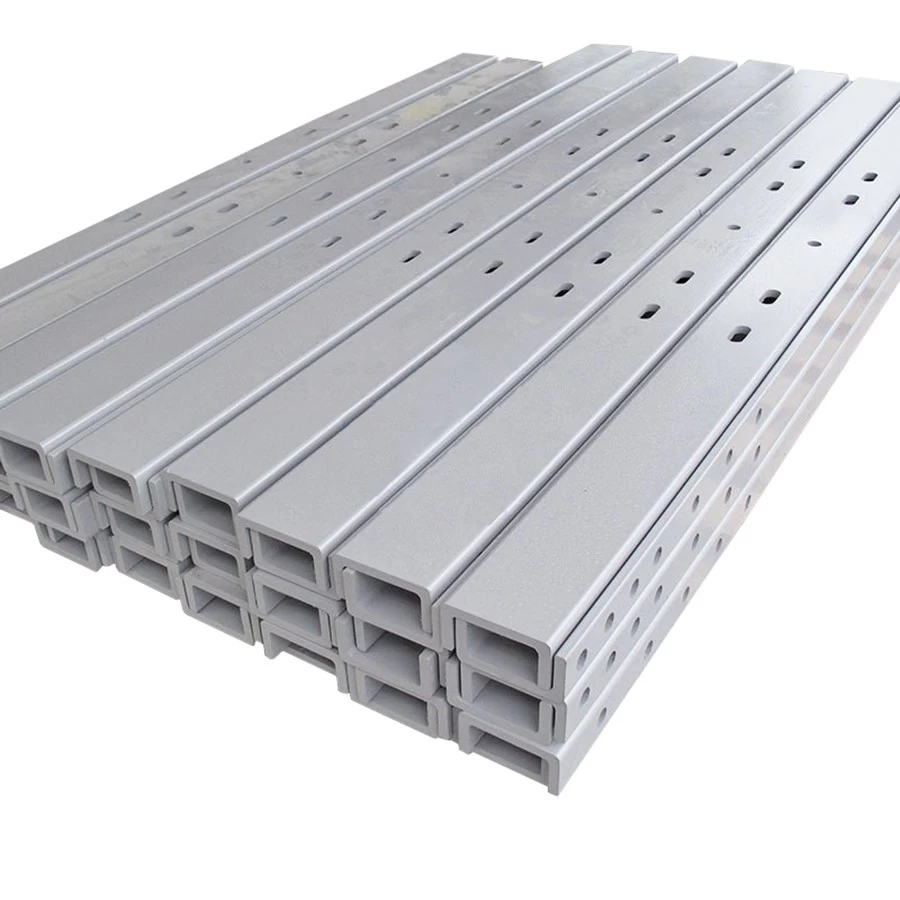

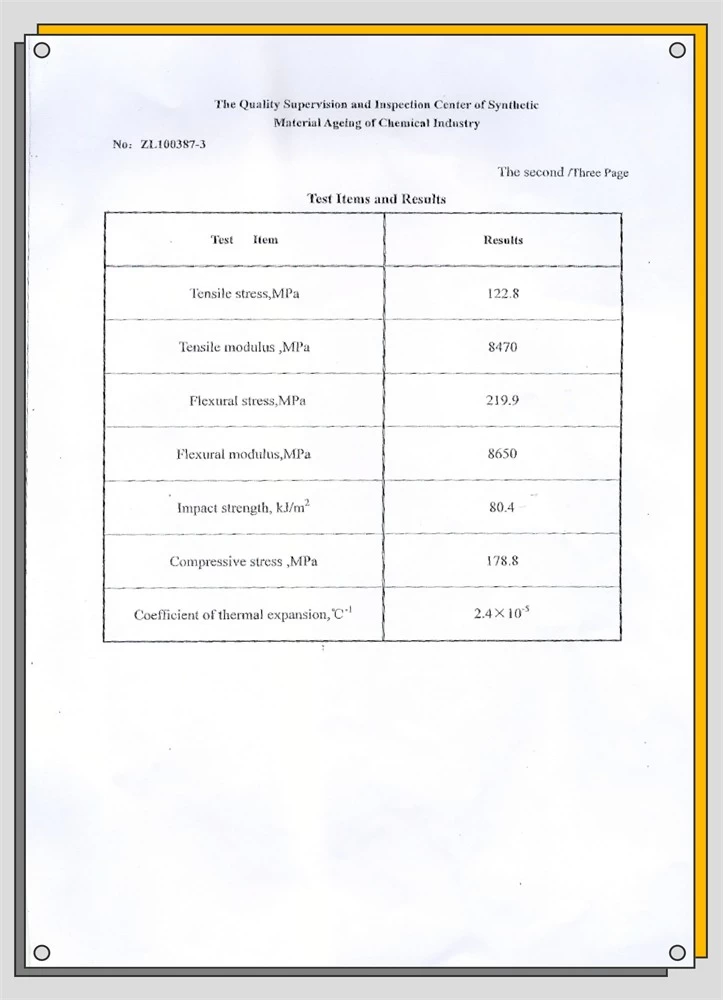

In the polyurethane pultrusion process, more reinforcing glass fibers can be used to greatly increase the strength of the product. At the same time, due to the excellent impact strength, tensile strength and interlayer shear strength of polyurethane itself, the products can be made thinner and lighter.

For example, thinner I-beams can be made with less continuous strand mat and more roving, reducing the thickness of the I-beam from 3.3 mm to 2.6 mm while maintaining its longitudinal stiffness. In this way, the product is reduced by 13% in weight and 7% in cost. In addition, because pultruded polyurethane products are less brittle, they can be assembled in conventional ways without cracking and shattering - datas from china frp pultrusion manufacturers Yuyi Tech.

Specifically, the use of polyurethane pultrusion has the following obvious advantages.

(1) As many as 4 or 5 different fiberglass mats may be required when pultruding certain profiles with conventional resins. These felts must be cut to shape. With polyurethane pultrusion, glass fiber roving can often be used instead of glass fiber mat. Elimination of fiberglass mats reduces raw material costs and labor costs for handling the mats. Felt is also prone to breakage, and fragments can clog machines and affect production. Elimination of felting increases line speed in many cases and thus improves cost-efficiency.

On the other hand, by replacing felt with roving, the fiber volume content can be increased to around 80%, compared to the 60% fiber content of most non-PU pultruded products. In this way, a higher glass fiber content is combined with a better-performing resin to create a polyurethane pultruded profile with improved strength and stiffness.

(2) The higher strength properties of polyurethane pultruded products have opened up some new applications. These articles can be used in applications where polyester resins cannot, replacing steel and aluminum in the construction, infrastructure and transportation markets.

(3) It is relatively simple, convenient and economical for china grp pultrusion factories to convert the original pultrusion system into a polyurethane pultrusion system without large investment. The original die head, heater and unit can still be used.

(4) In addition to the above-mentioned physical properties and molding advantages, polyurethane pultrusion products also have assembly advantages, especially fastening convenience. Due to the strength of polyurethane, no pre-drilling is required to insert screws into polyurethane pultrusions, which saves time and labor. Conversely, the force required to pull out a screw in polyurethane pultrusion was more than twice that of polyester pultrusion.

(5) Under the same fiber structure, all properties of polyurethane/glass fiber pultruded products are better than those of ordinary thermosetting resins, the bending modulus is close, the impact strength is greatly improved, the screw pullout strength is high, the opening has good resistance to crack expansion, and is wear-resistant Excellent performance, good secondary processing ability, heat resistance above 240 degrees.

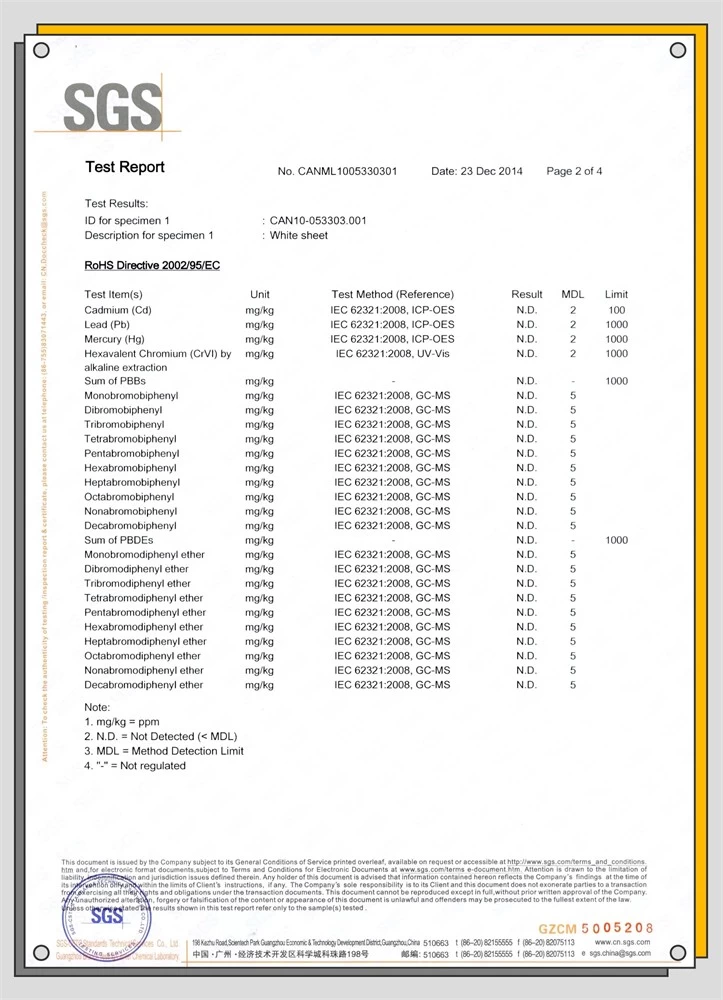

(6) Pure polyurethane/glass fiber is currently the best pultrusion composite material with complex cross-section, smooth surface, fast pultrusion speed, the best resistance to water, acid, alkali and salt, good flame resistance, and can be painted Packing, aliphatic polyurethane system, solvent-free, styrene-free, environment-friendly.

For more FRP Pultruded sections, please click china pultruded grp suppliers