The Main Application of Fiberglass Reinforced Polyurethane Materials

The article, written by china fiberglass pultrusion manufacturers, which is talking about some applications of Fiberglass Reinforced Polyurethane materials, also known as GFRU (glass fiber reinforced PU resin).

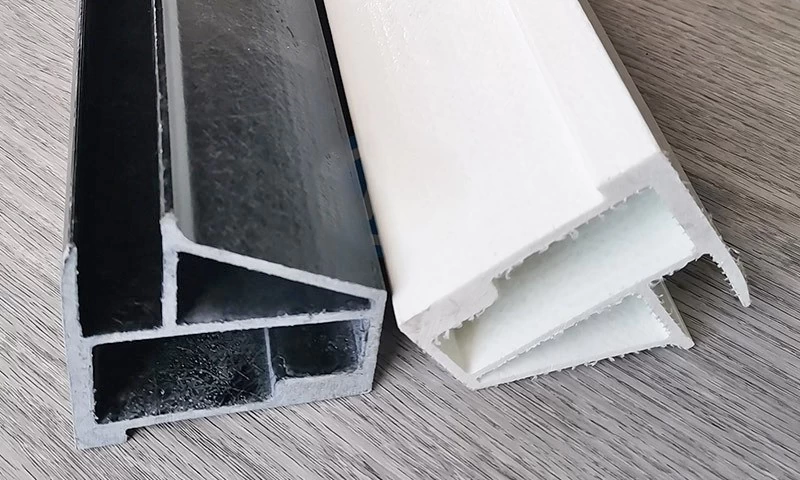

1) For building - pultruded window frames

In buildings, doors and windows, exterior walls, roofs and grounds are the four main energy consumption parts of buildings, and doors and windows have the worst thermal insulation. Therefore, enhancing the thermal insulation performance of doors and windows and reducing the energy consumption of doors and windows is an important link to improve the quality of indoor thermal environment and improve the level of energy saving in buildings.

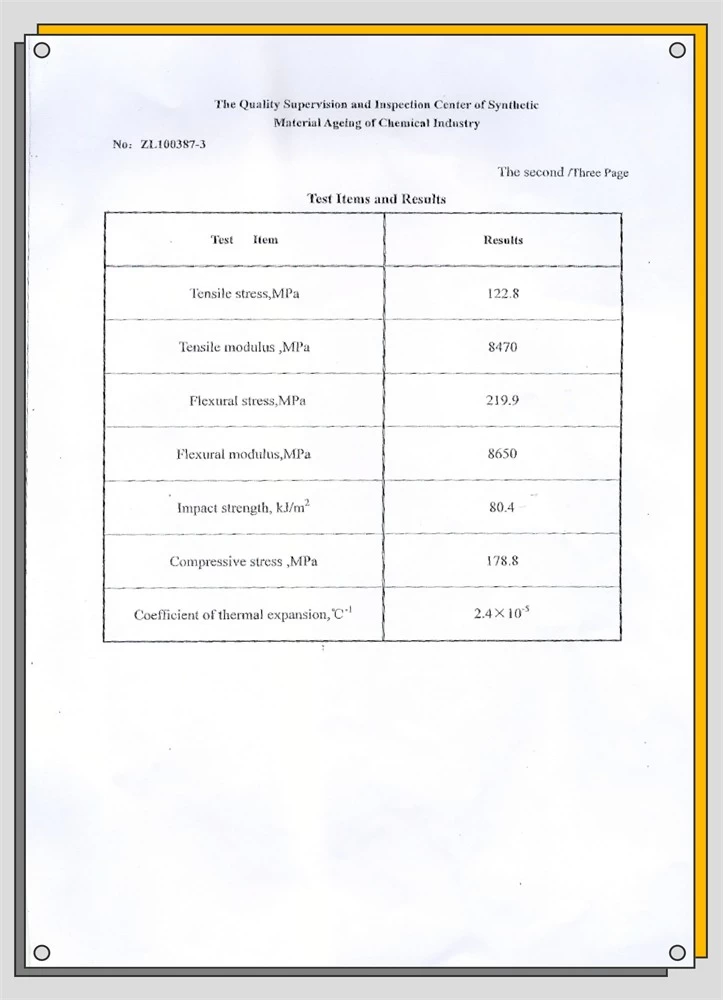

- GRPU profile has a very low thermal conductivity, which is 0.22 W/m•K at room temperature, only about 1/700 of that of aluminum alloy, and is an excellent thermal insulation material.

- The linear thermal expansion coefficient of GRPU is about 7×10-6/K, which is much lower than that of aluminum alloy and similar to that of the wall; therefore, when the temperature changes, the frame made of GRPU will not have a gap with the wall. Good sealing.

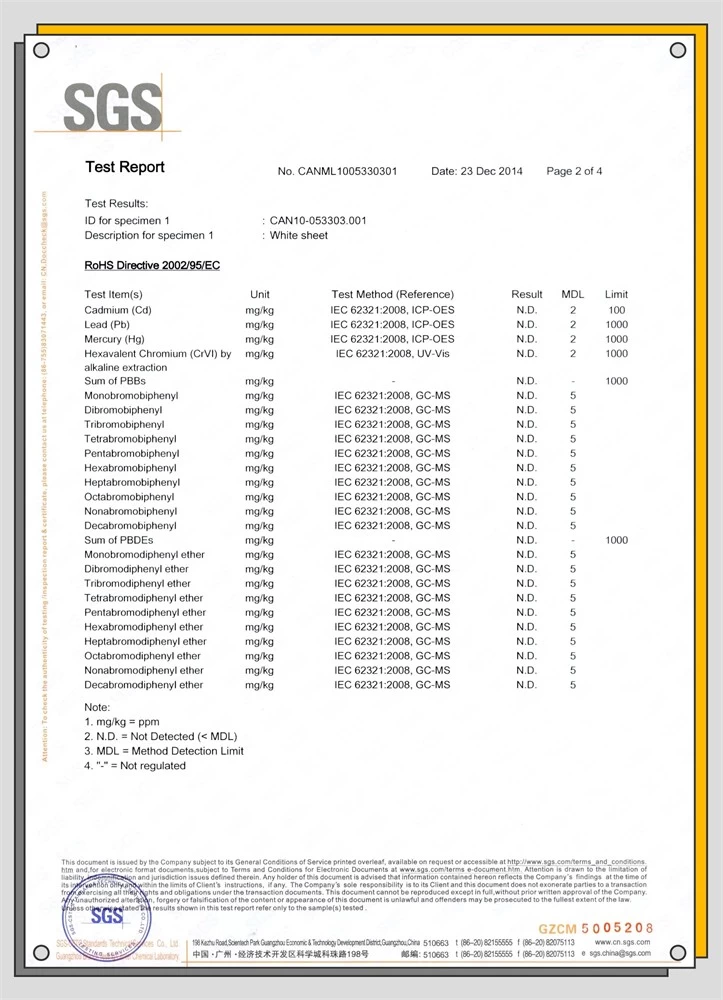

- GRPU profiles have strong corrosion resistance to most acids, alkalis, salts, organic substances, as well as sea water and humid air; and they are stainless and immortal, and their corrosion resistance is better than other material door and window profiles. Especially suitable for coastal, corrosive and generally wet places.

- GRPU profile is a good insulating material, not affected by electromagnetic waves, and does not reflect radio waves; it has special uses for the construction of communication systems.

Datas provided by china frp profiles suppliers

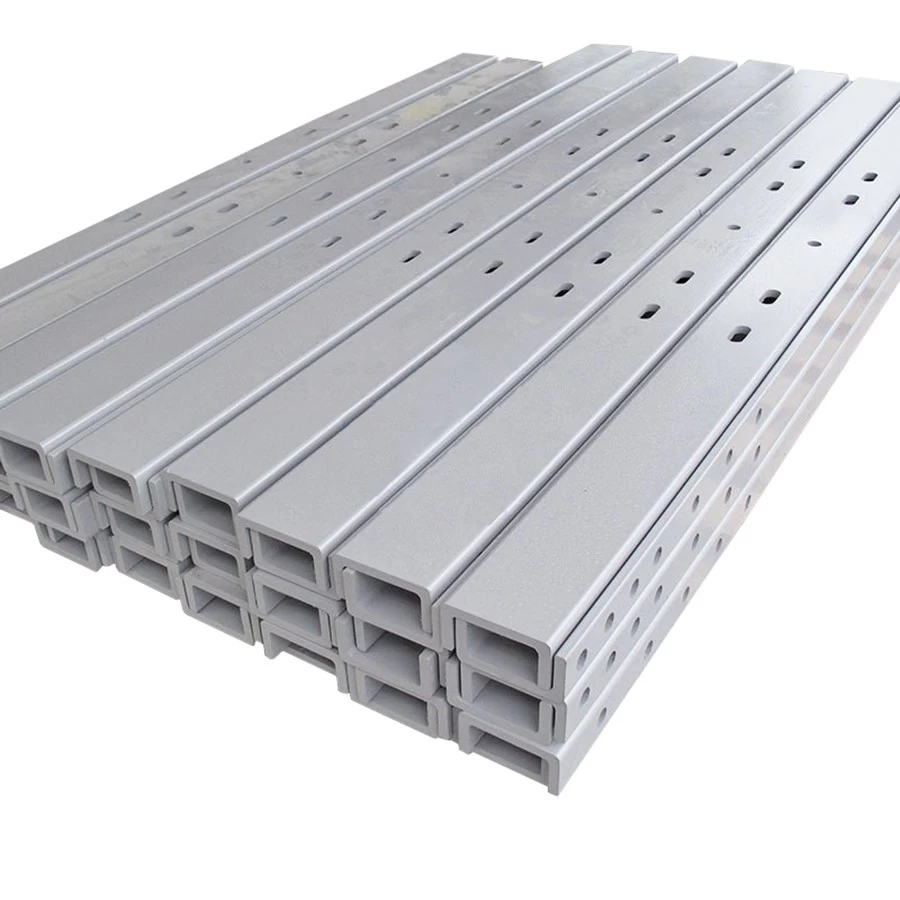

2) Container floor - more "light" and more durable

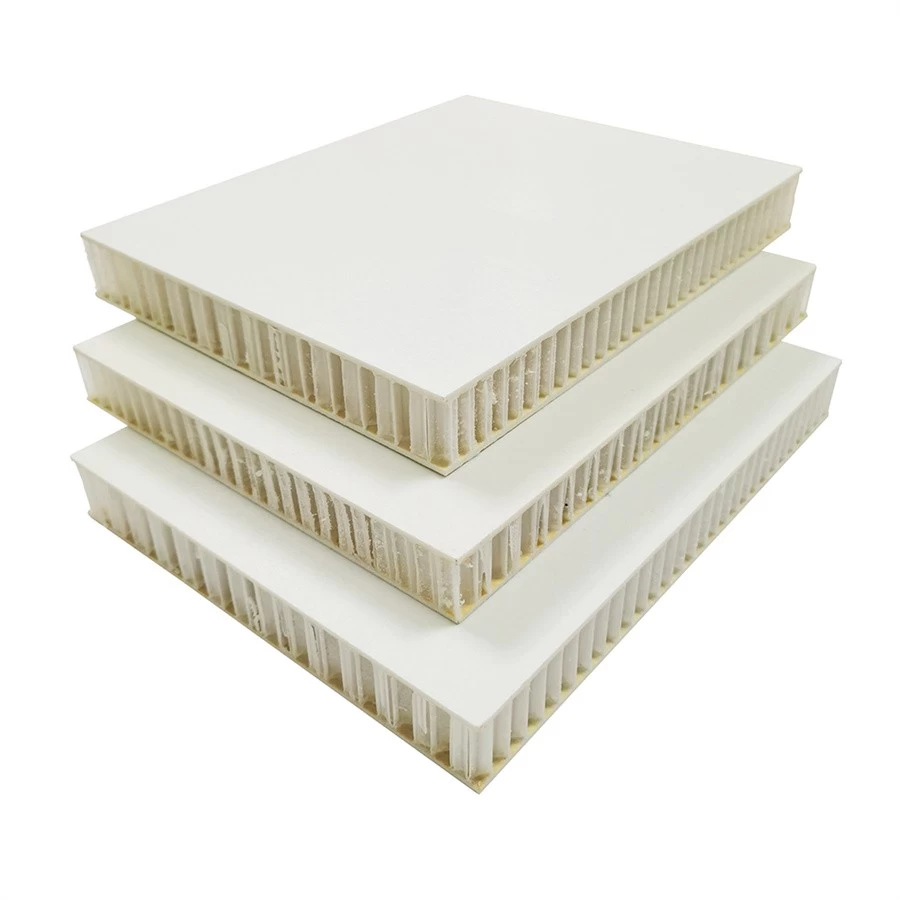

Polyurethane / glass fiber composite floor system, due to the material's high pultrusion efficiency, high strength and rigidity, as well as excellent impact resistance and abrasion resistance, has added a lot to the container transportation industry.

Compared with traditional wood-based materials, the weight of materials using polyurethane extrusion technology will be reduced by 22%, and the fuel consumption and transportation costs of the entire ship and container will be greatly reduced. While being lightweight, it maintains sufficient toughness and performance. This feature also reduces maintenance costs and increases the service life of the container. The service life of traditional container wood floors is only 5 to 10 years, while the service life of polyurethane pultrusion floors can exceed 20 years.

3) Railway sleepers - FFU sleepers

Said to look like wood, the sleepers combine all the advantages of a natural product and modern design. It can be sawed, planed, nailed, screwed and glued with common woodworking tools. Its thermal expansion coefficient and thermal conductivity are very low. Due to fiber reinforcement, its compressive, tensile and bending strengths are all high, and its service life is more than three times longer than that of traditional sleepers. Due to its closed-cell structure, it absorbs very little water even in heavy rain, thus not affecting its excellent electrical insulation properties.

The material is also resistant to hydrolysis, grease, seawater, frost and de-icing salts and remains stable in long-term climate conditions. Its weight and on-site processing performance are much better than concrete, and can be made into any length, without the need to make separate molds for each length. Its ecological performance is also a big plus, as it is manufactured without the use of solvents and can be recycled after use.

Due to these advantages, FFU sleepers are especially suitable for use in tunnels and bridges.

This photo shows the Power cross arm produced by china fiberglass profiles factories

4) Other uses

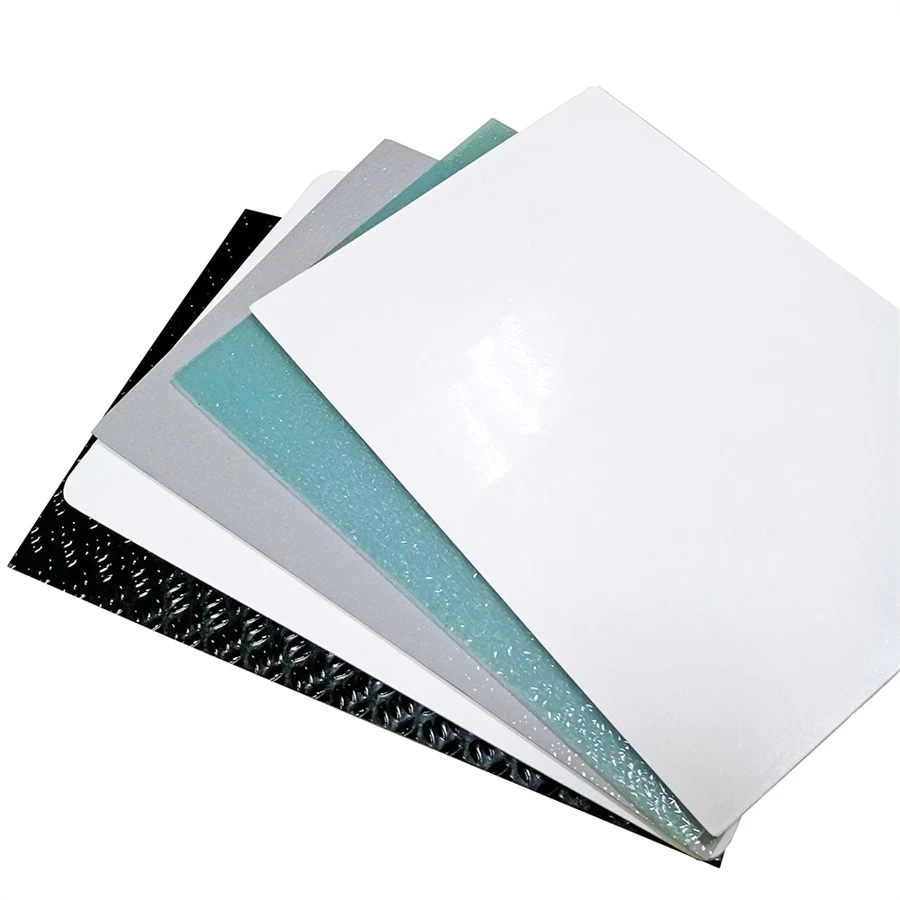

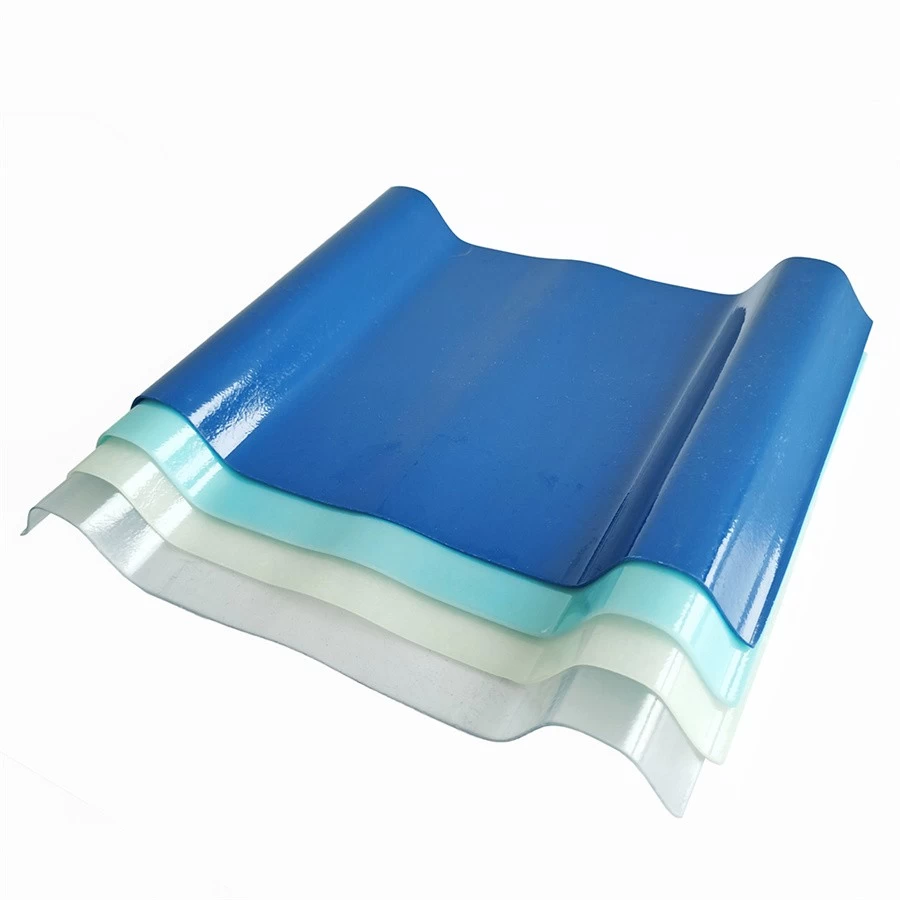

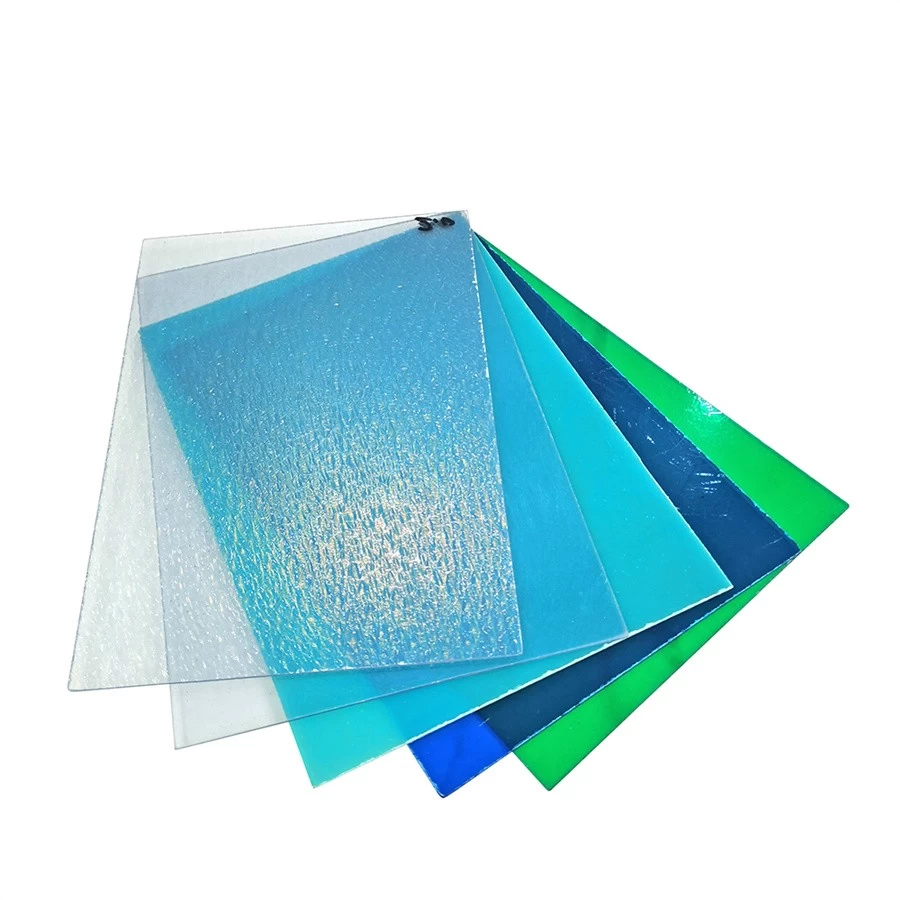

Polyurethane pultrusion products include profiles, rods and plates, such as ladder poles, tool handles, utility pole crossarms, poles, hockey sticks, dock piles, container plates, etc.