Application of Fiberglass Reinforced Materials in Automobile Lightweight

Global automobile production and sales have been increasing year by year, and at the same time, problems such as environmental pollution and energy supply difficulties are becoming more and more serious. With the development of society, the application of materials in the automotive field tends to be lightweight. A single plastic material has been difficult to meet market demand. The research and use of composite materials has become the development direction of automotive materials.

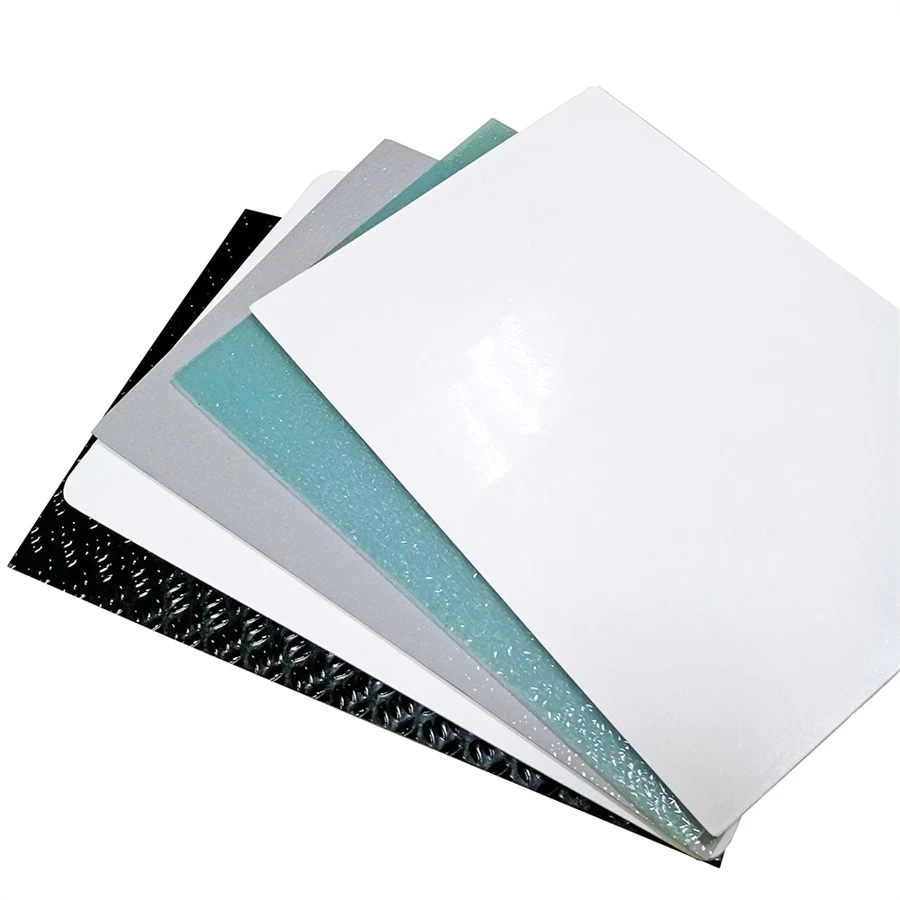

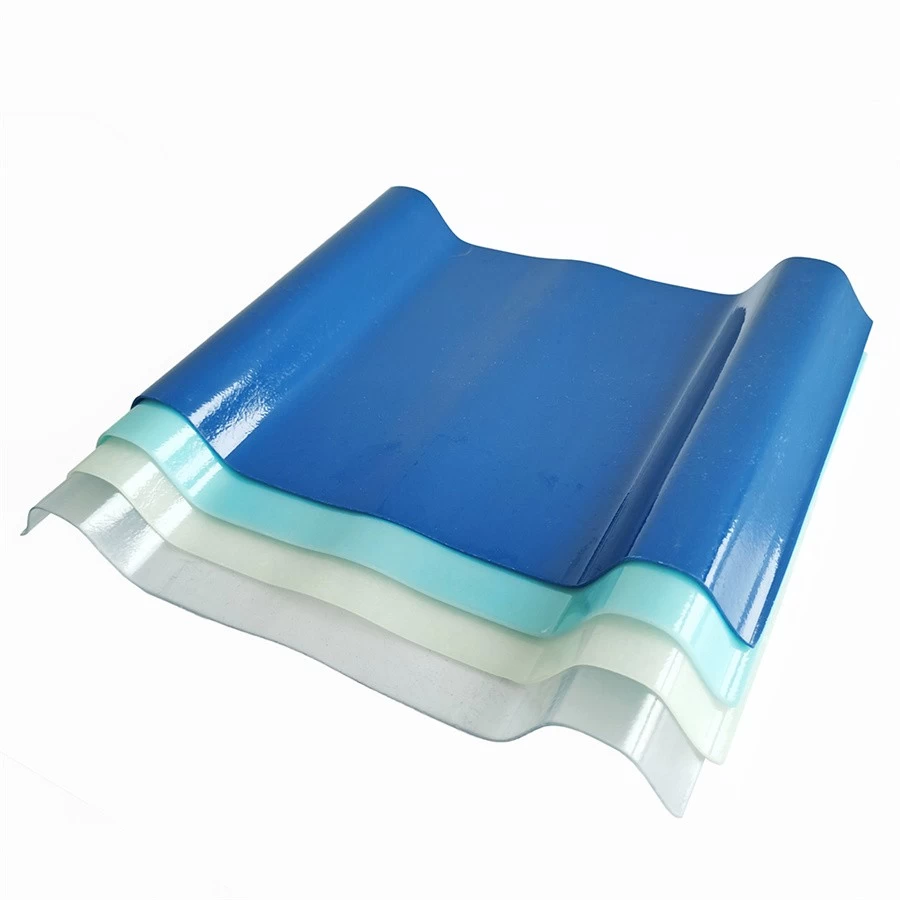

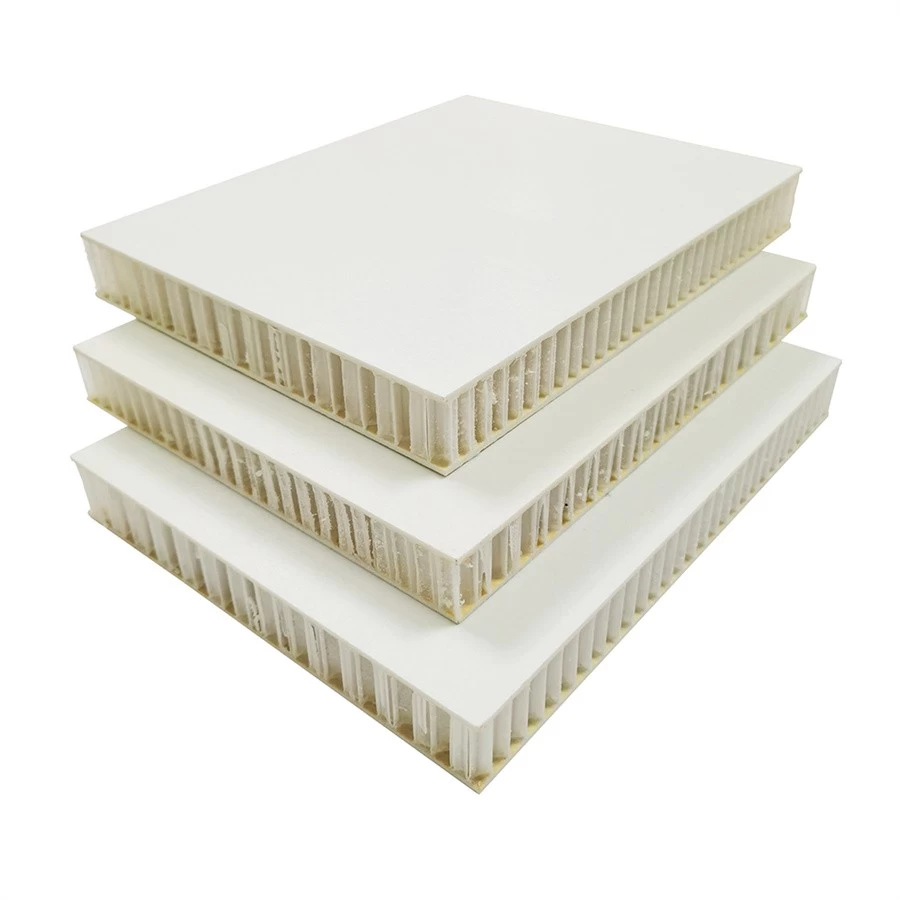

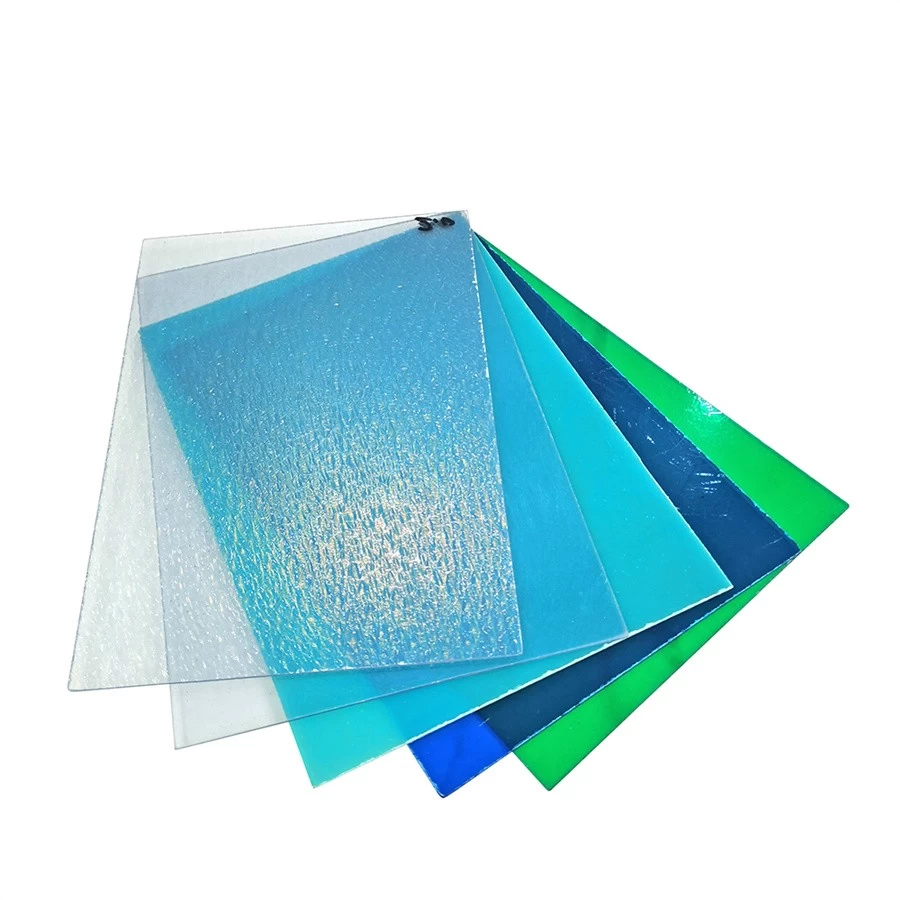

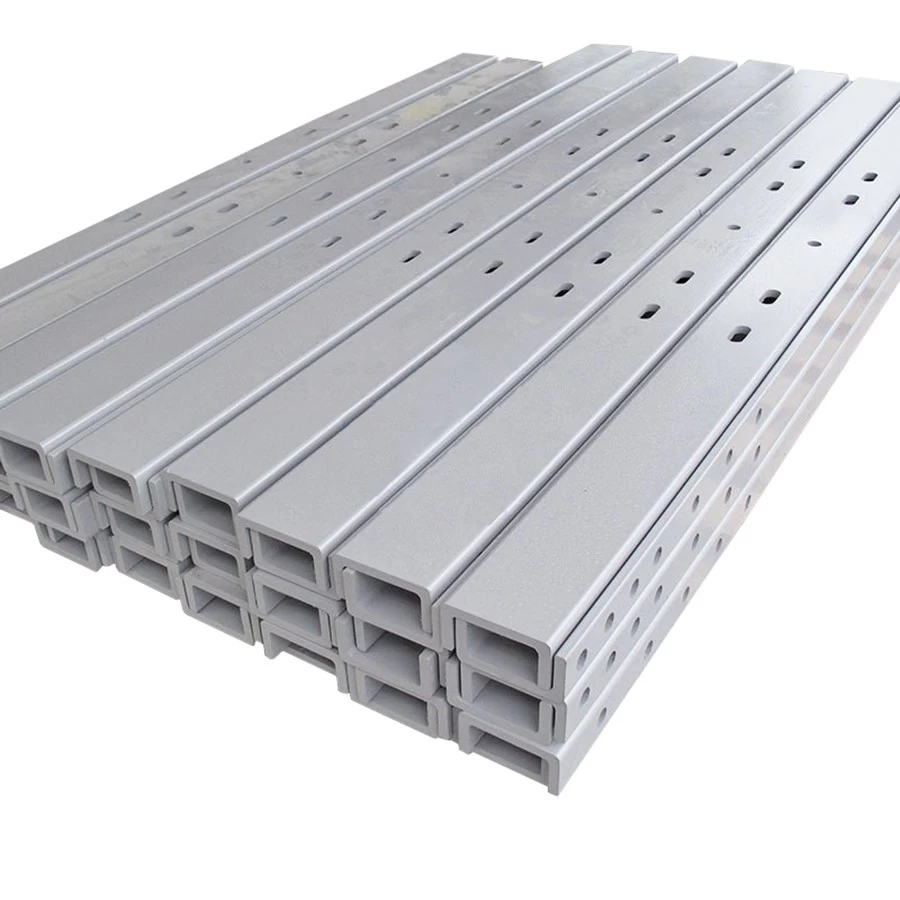

Fiberglass reinforced plastic composite materials provided by china grp panel manufacturers have good corrosion resistance, comfort, flexibility, friction resistance, impact resistance, and easy processing. They are widely used in the lightweight technology of automobiles, which can not only reduce the weight of the automobile itself, but also It can ensure the driving safety of the automobile and reduce the production cost of the automobile at the same time.

Application significance in automobile lightweight

- Effectively reduce the weight of the car. Among the metal materials, the specific gravity of A3 steel and brass is greater than 7, and the specific gravity of aluminum is lighter, but it is also 2.7. Most plastics have a specific gravity between 0.9 and 1.5, and fiber-reinforced composites panels have a specific gravity of less than 2. More and more companies use china FRP Panels instead of metal materials in automobile lightweight technology to reduce the total weight of the car and increase the payload.

- An effective path for automobile energy saving and emission reduction. Automotive plastic products are used in car decoration, etc., which can make the design more flexible and the car shape more beautiful. Plastic products have various functions such as corrosion resistance, wear resistance, heat insulation, noise reduction, and vibration reduction, which can improve power, adapt to harsh environments, and increase vehicle safety. In addition, the use of plastic products to reduce the weight of the vehicle can reduce fuel consumption and reduce exhaust emissions. At the same time, light weight can also improve the battery life of new energy vehicles.

- It can reduce the production cost of automobiles. Using glass fiberg reinforced products produced by china fibreglass reinforced panels factories instead of metal and other materials as materials can not only reduce the cost of materials, but also save material processing and maintenance costs, thereby reducing the cost of automobile production. For example, a simple injection-molded plastic part can weld many metal parts together. In addition, plastic can be molded into more complex and diverse shapes than other materials, thereby reducing the use of parts.