- Browse Categories

- FRP Sheet

- FRP Composite Panel

- Other Composite Panel

- Pickleball Paddle & Panel

- FRP Molded Grating

- FRP Pultrusion

- Contact Us

-

Customer Service

Shenzhen Yuyi Technology Co., Ltd

Phone: +86 0755 33228547

Mobile: +86 18567663609

Email: info@frppanlesupplier.com Contact Now

- Hot Produts

- New Products

- News

-

-

Main Purpose of FRP Panels

FRP materials have been successfully used in the field of anti-corrosion for more than 80 years, such as chemical storage tanks, underground water supply and drainage pipelines, offshore cruise ships, wind power facilities, etc. Its excellent anti-corrosion and aging resistance have been widely recognized. -

What are the construction materials of rock climbing walls?

The artificially designed rock walls are more and more sought after and loved by the masses, and their construction materials are mainly divided into FRP sandwich panel, wooden board and engineering plastic. -

FRP Panels for Outer Skin of Transport Tank

In addition to being used on refrigerated trucks, FRP panels can also be used on cooling tower bottom plates, mobile homes and trailers. But few people know that the FRP flat can also be applied to the outer skin of the tank truck. -

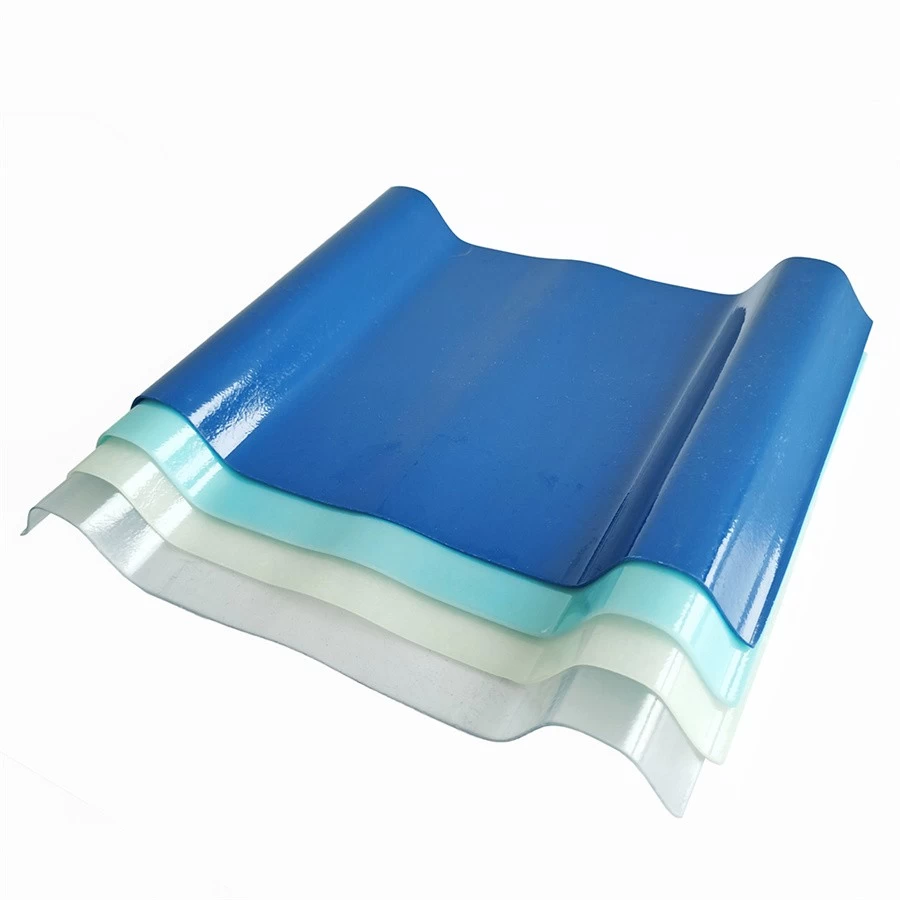

Raw Materials of Continuous Molding Process of FRP Roof Panel

FRP roof panels raw materials include: fiberglass chopped strand mat, resin matrix,Anti-aging surface layer and fillers. This article gives a brief introduction.

-

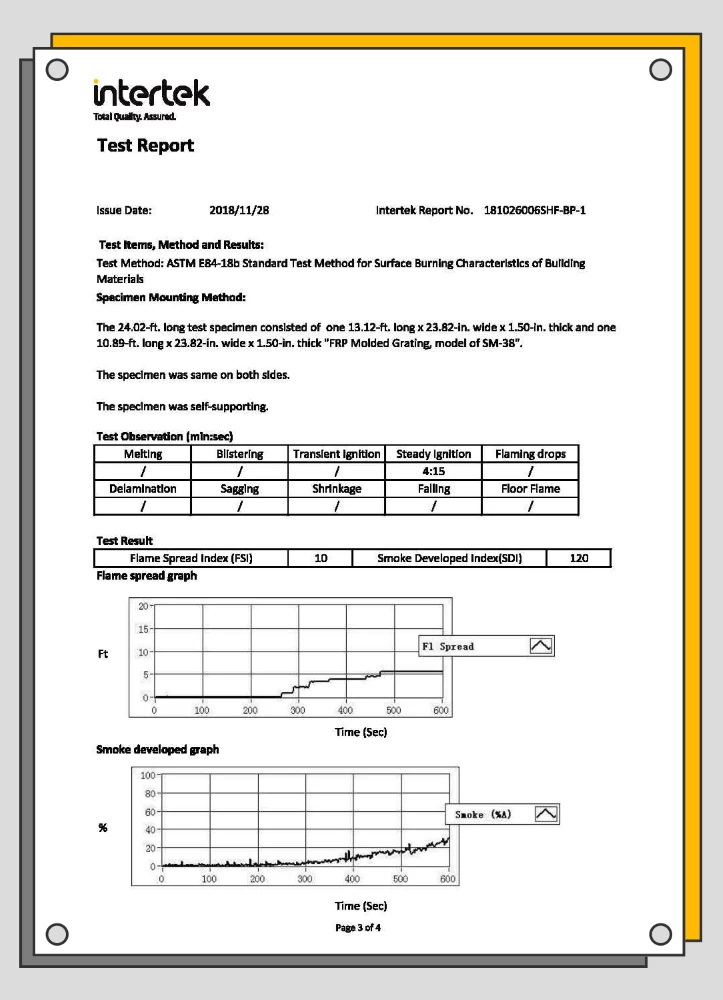

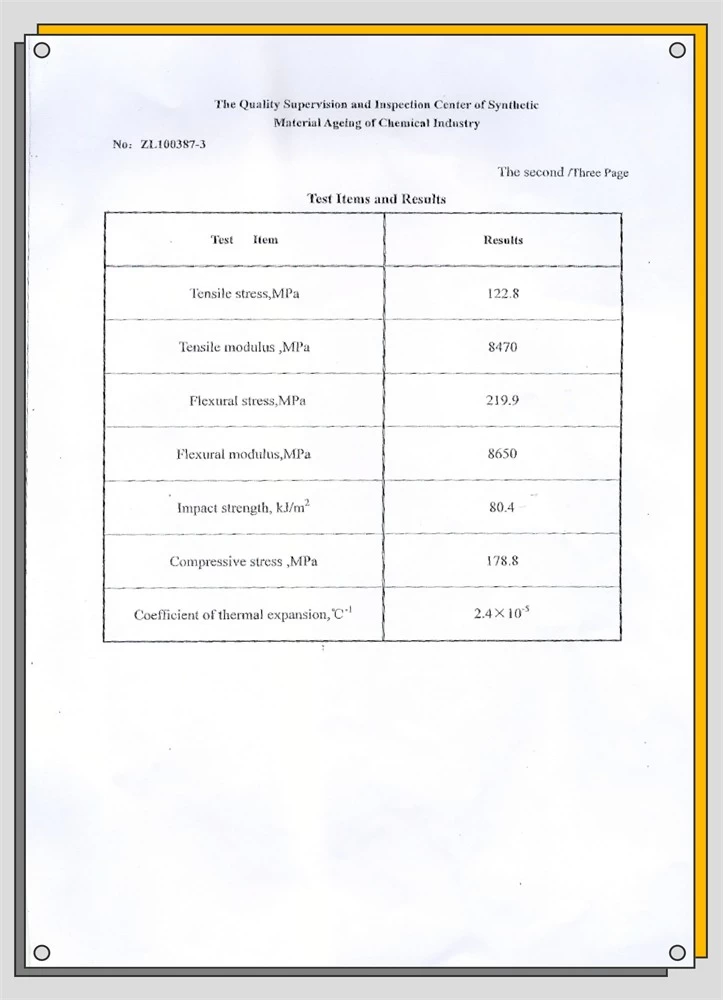

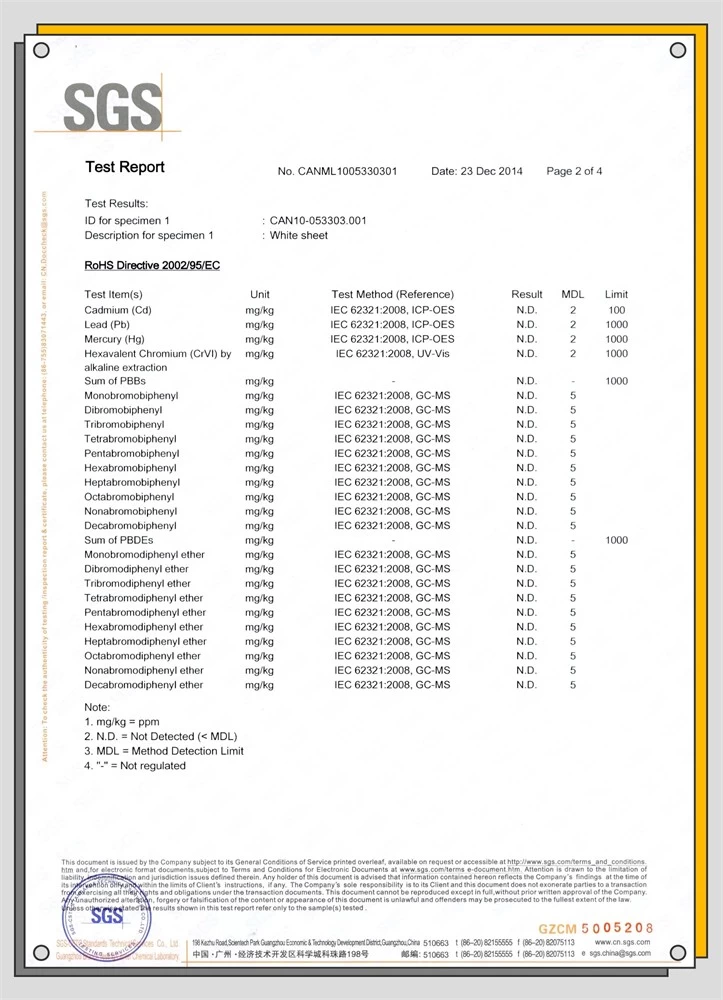

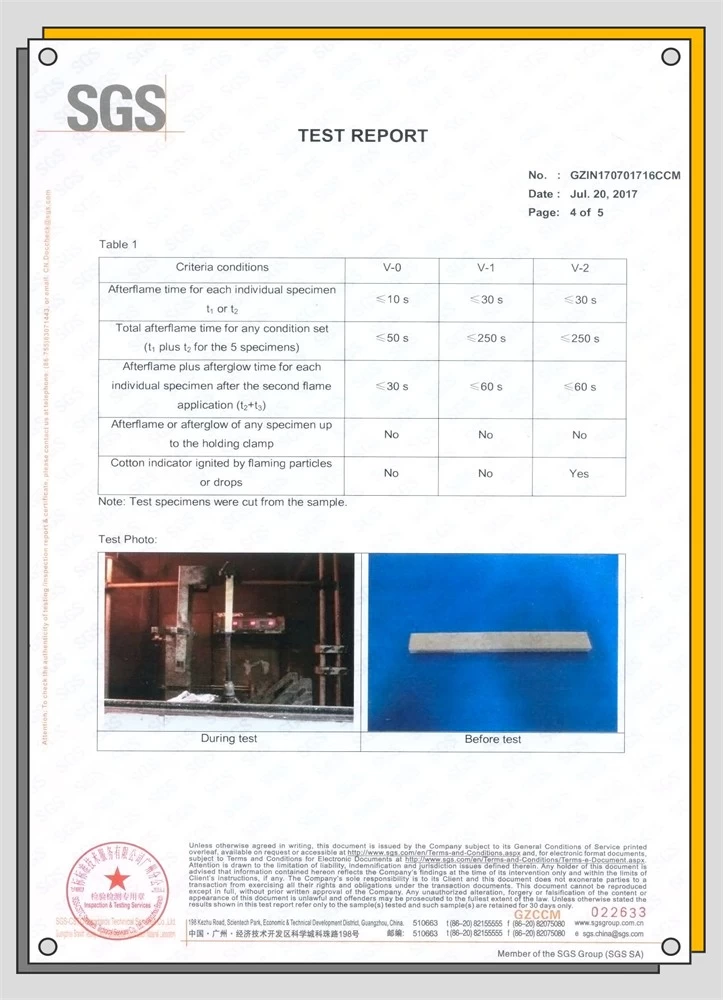

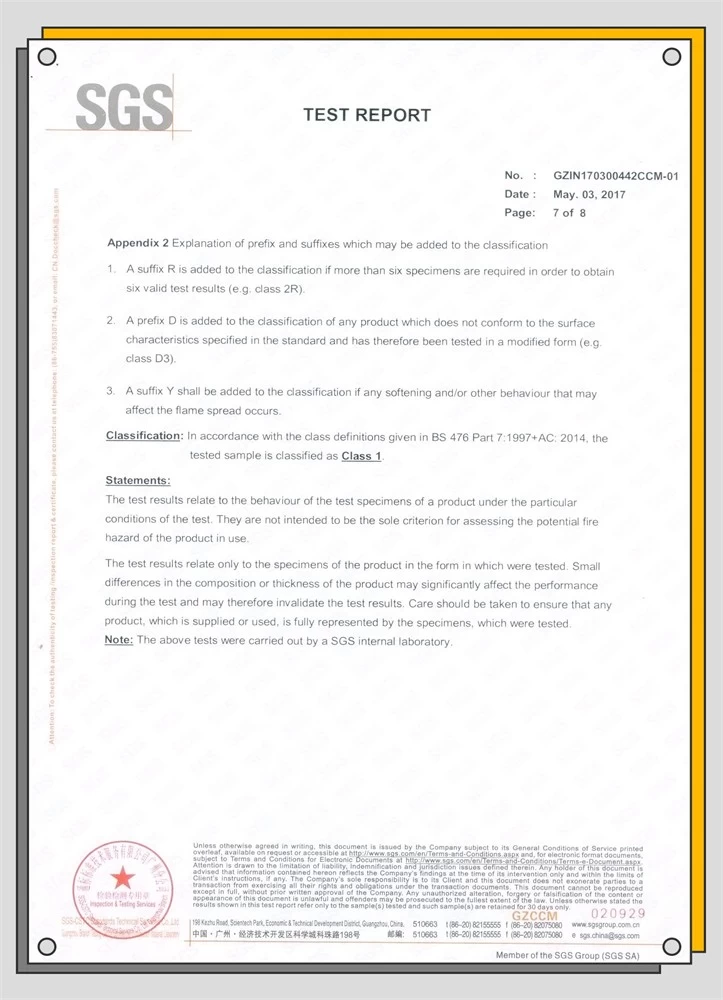

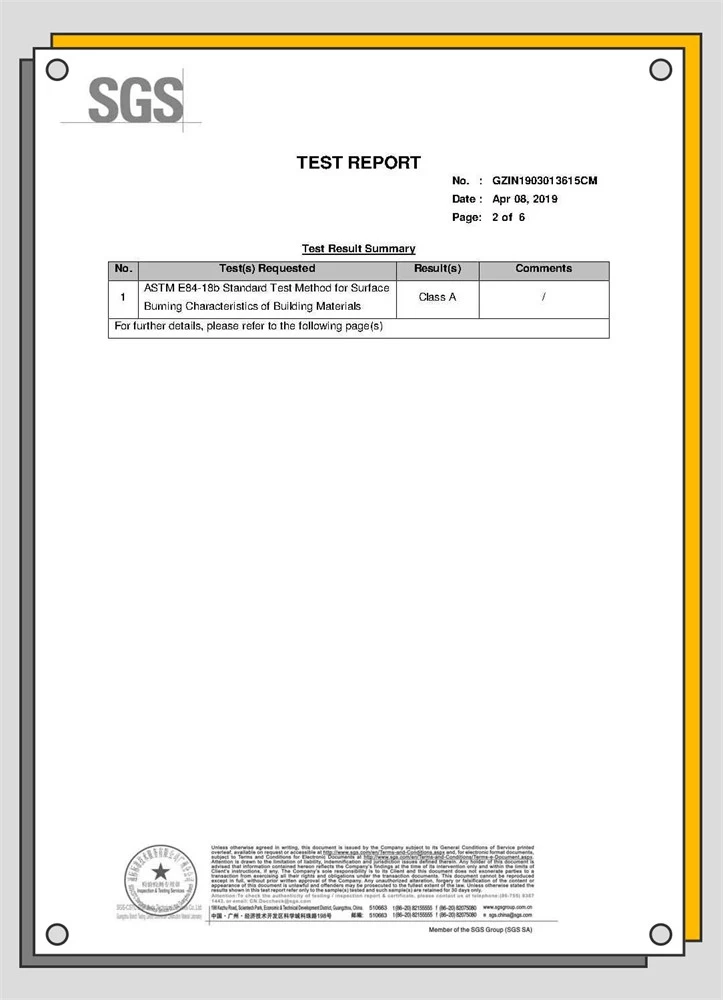

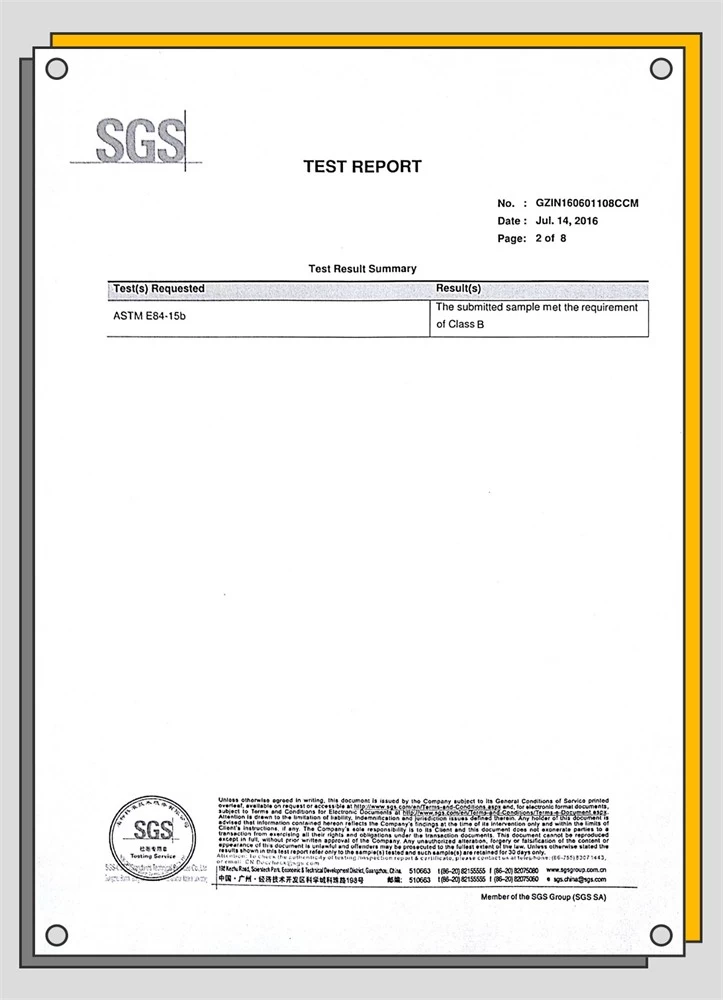

- Certifications

-

- Subscribe

-

Get email updates on new products

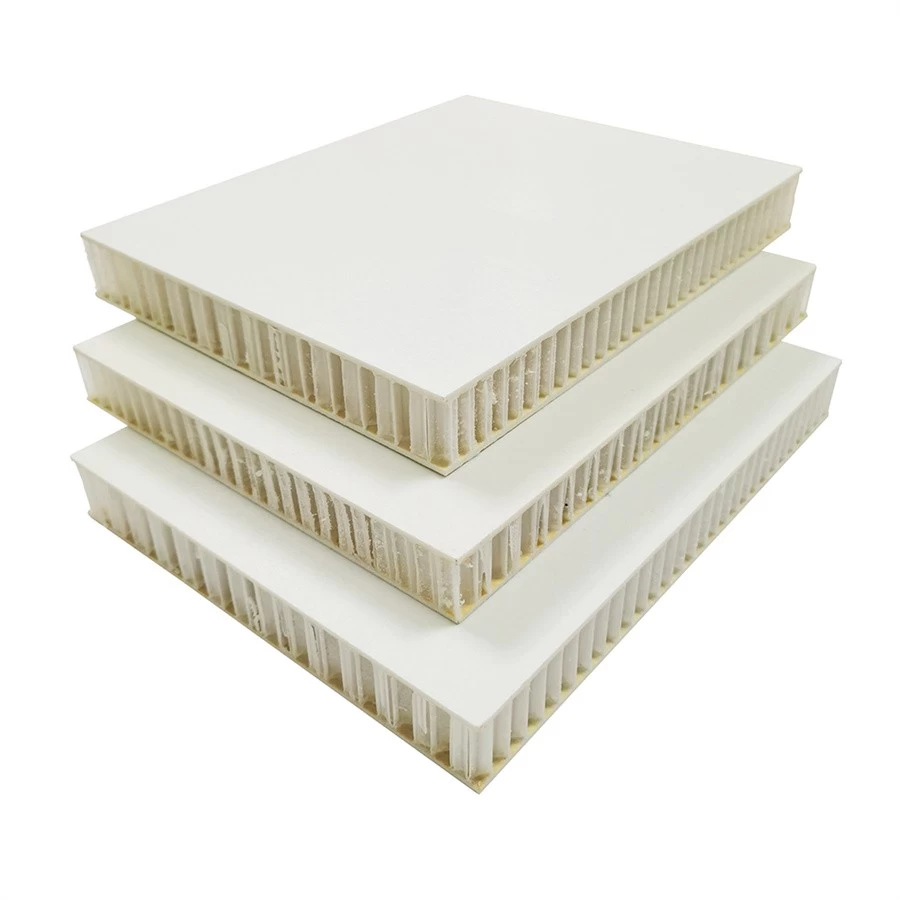

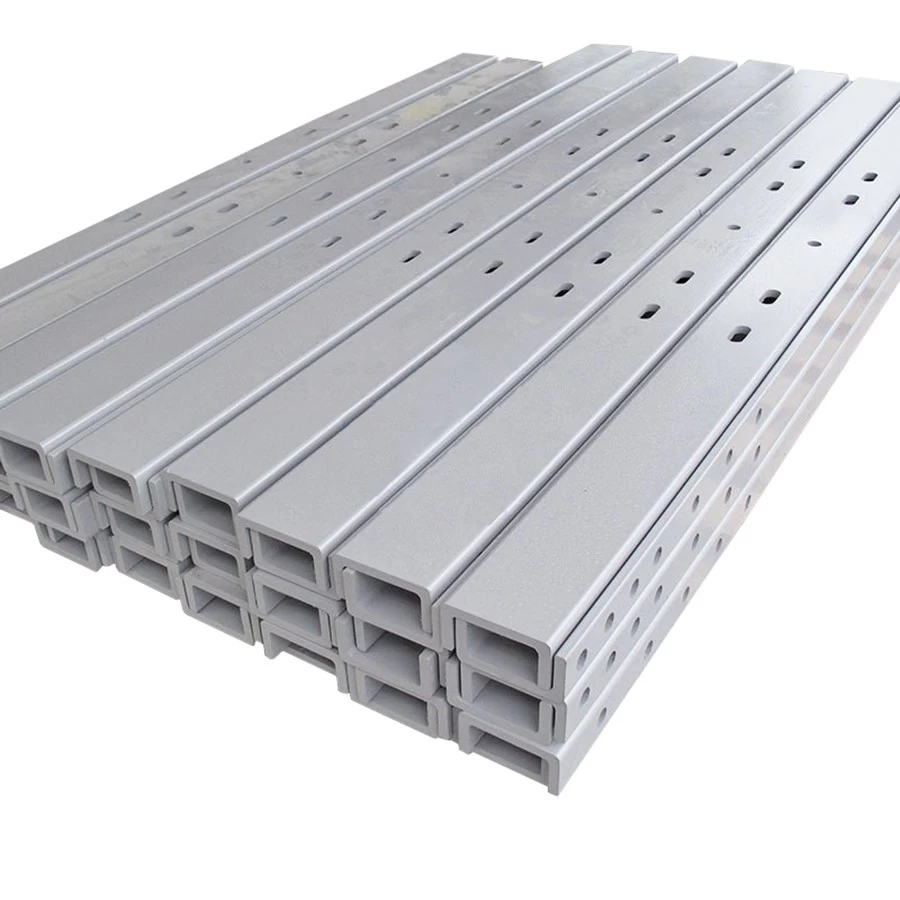

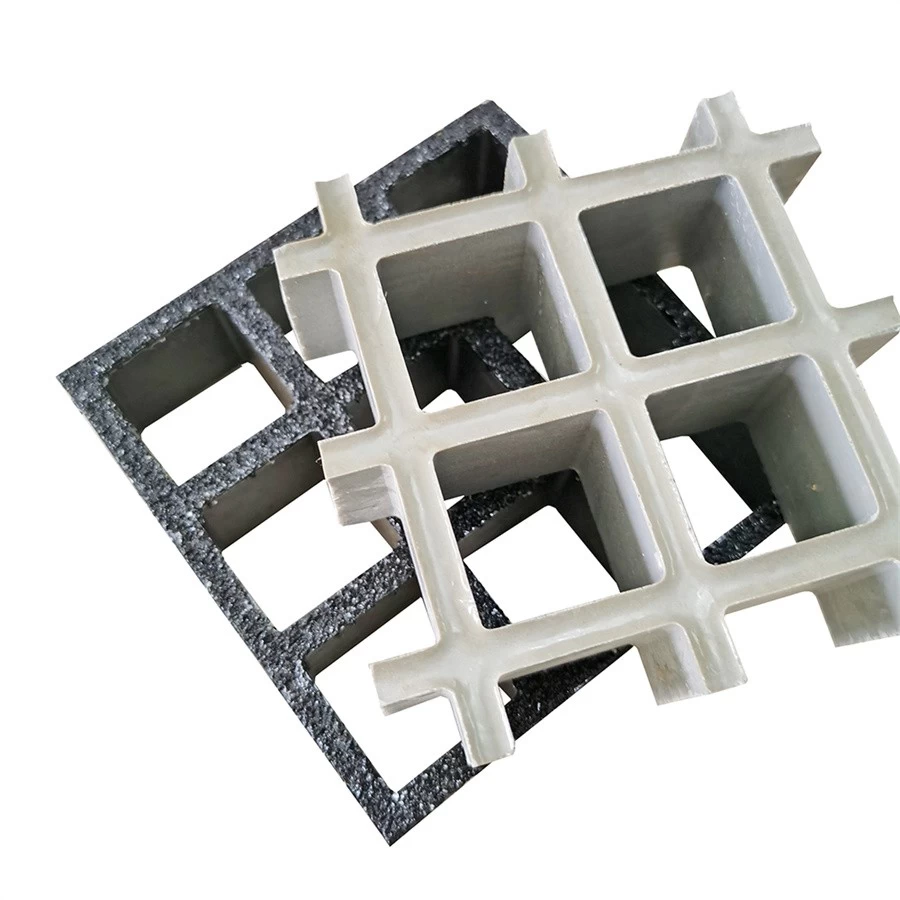

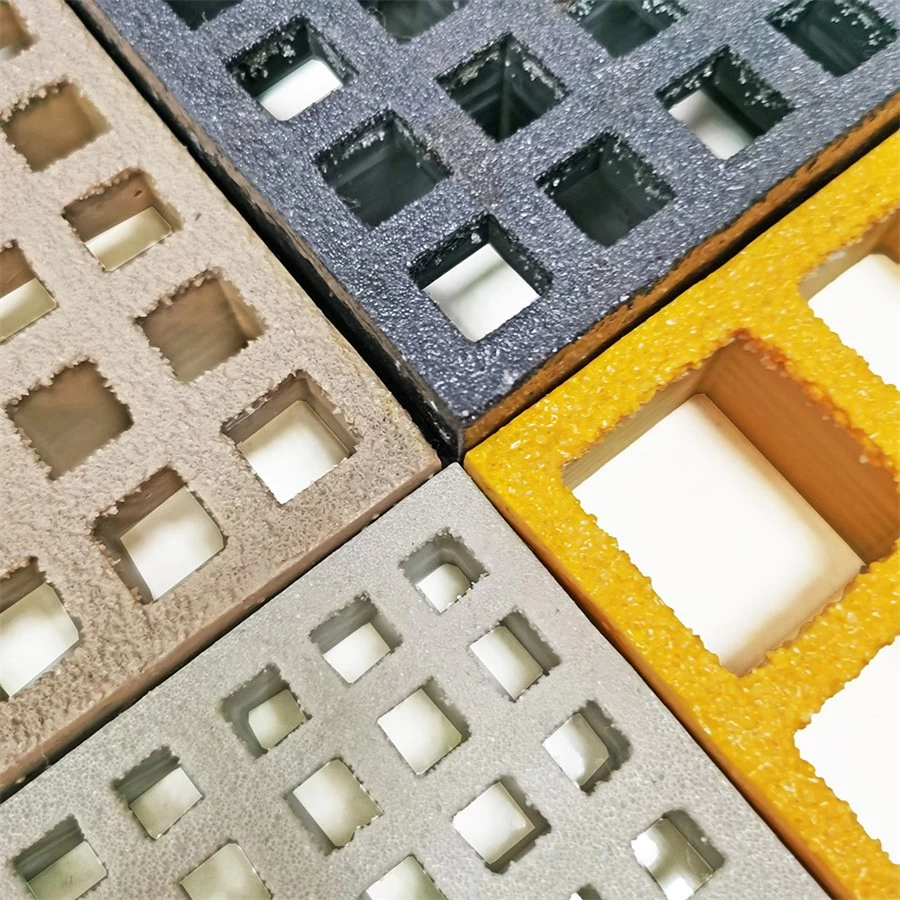

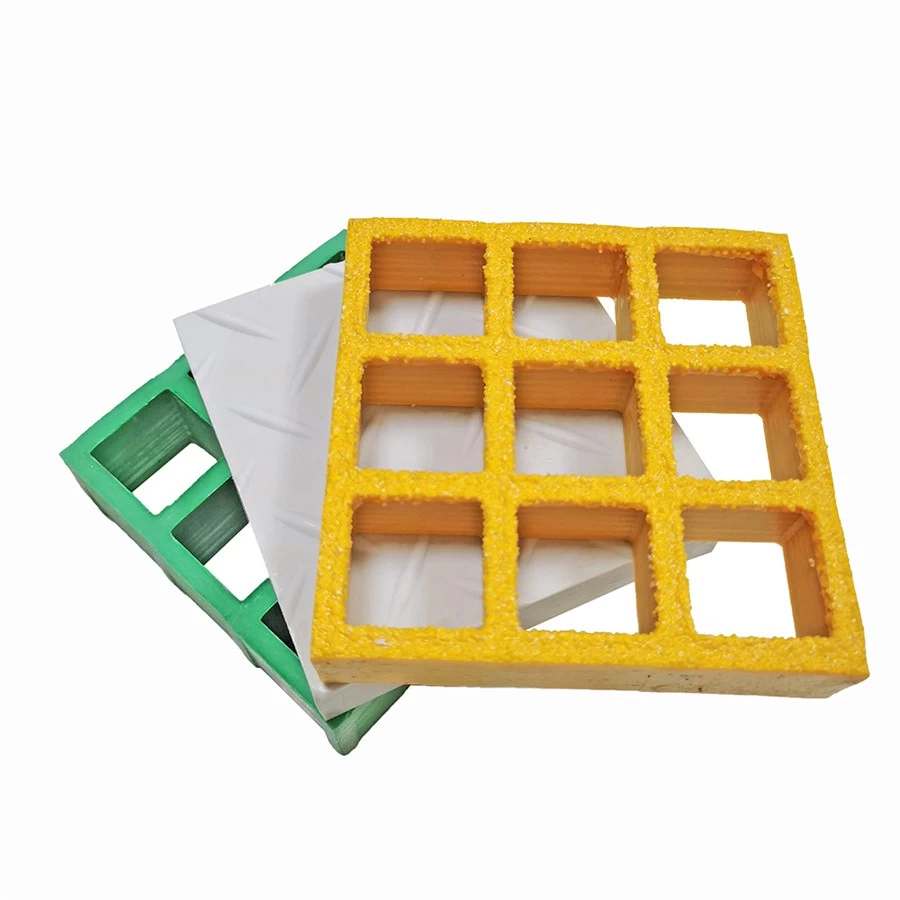

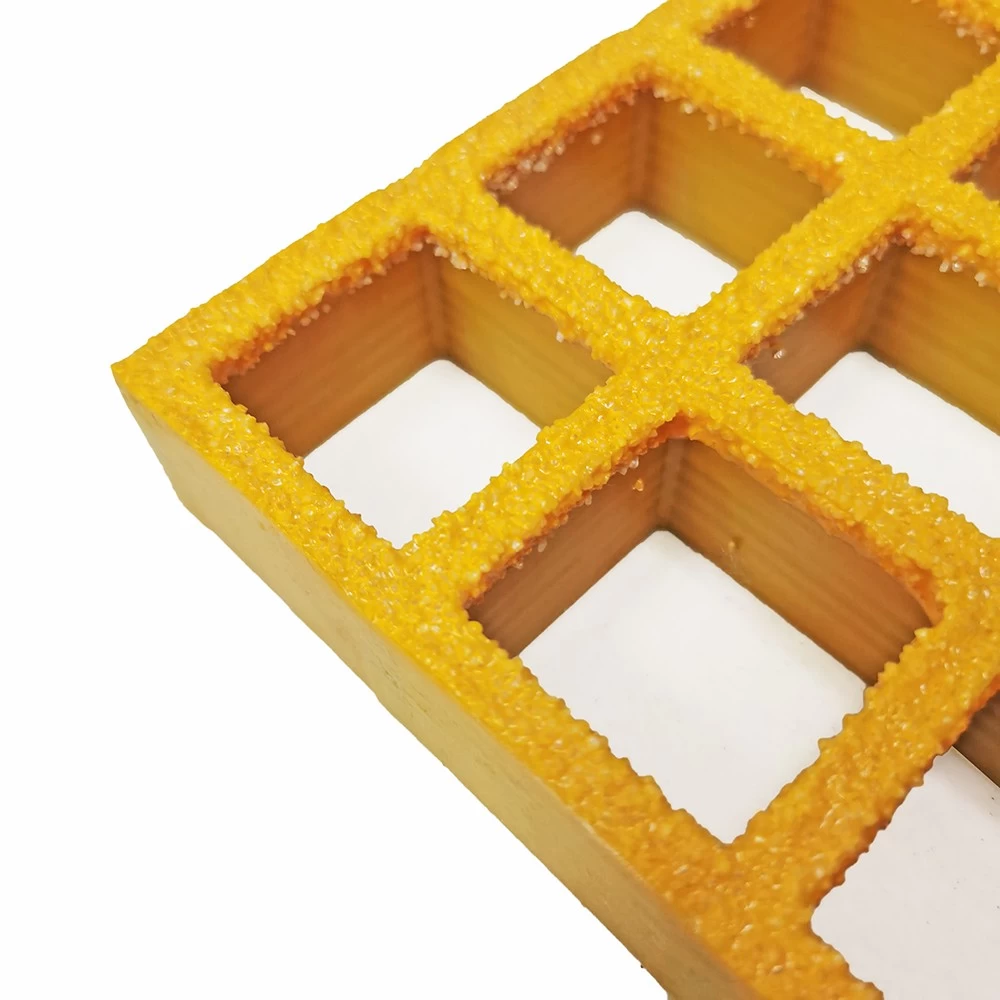

Molded Floor Walkway Open Mesh Glass Fiber Reinforced Plastic GRP Grating

- Thickness: 20, 25, 30, 38, 50, 60, 70mm

- Size: 1220x3660mm standard, or customized

- Color: Green, Grey, Black, Yellow, Red etc customized

- Surfaces: Concave, Griited, Mini mesh, Covered

- Fire Rated: General or ASTM E84 Class A

Molded Floor Walkway Open Mesh Glass Fiber Reinforced Plastic GRP Grating

Yuyi molded FRP Grating (Fiberglass Grating, GRP Grating) is manufactured in an open, heated mold system. Continuous E-glass roving's are placed in the mold in alternating layers and completely wetted with polyester resin, This continuous process produces an integral, one piece construction FRP gratings which provides excellent corrosion resistance as well as bi-directional strength. We have varity of different molds available so that a extensive range of panel sizes, tihckness and mesh types can be choosed.

Molded FRP Grating Addvantages

- Lightweight weight high loading strength

- Anti-corrosion and anti-aging

- Fire-retardant

- Non-conduction or magnetic

- Long service life and maintenance free

- Easy installation and rich choices

Molded FRP Grating Suface Types

| Cancave | Gritted | Covered | Mini Mesh |

|

|

|

|

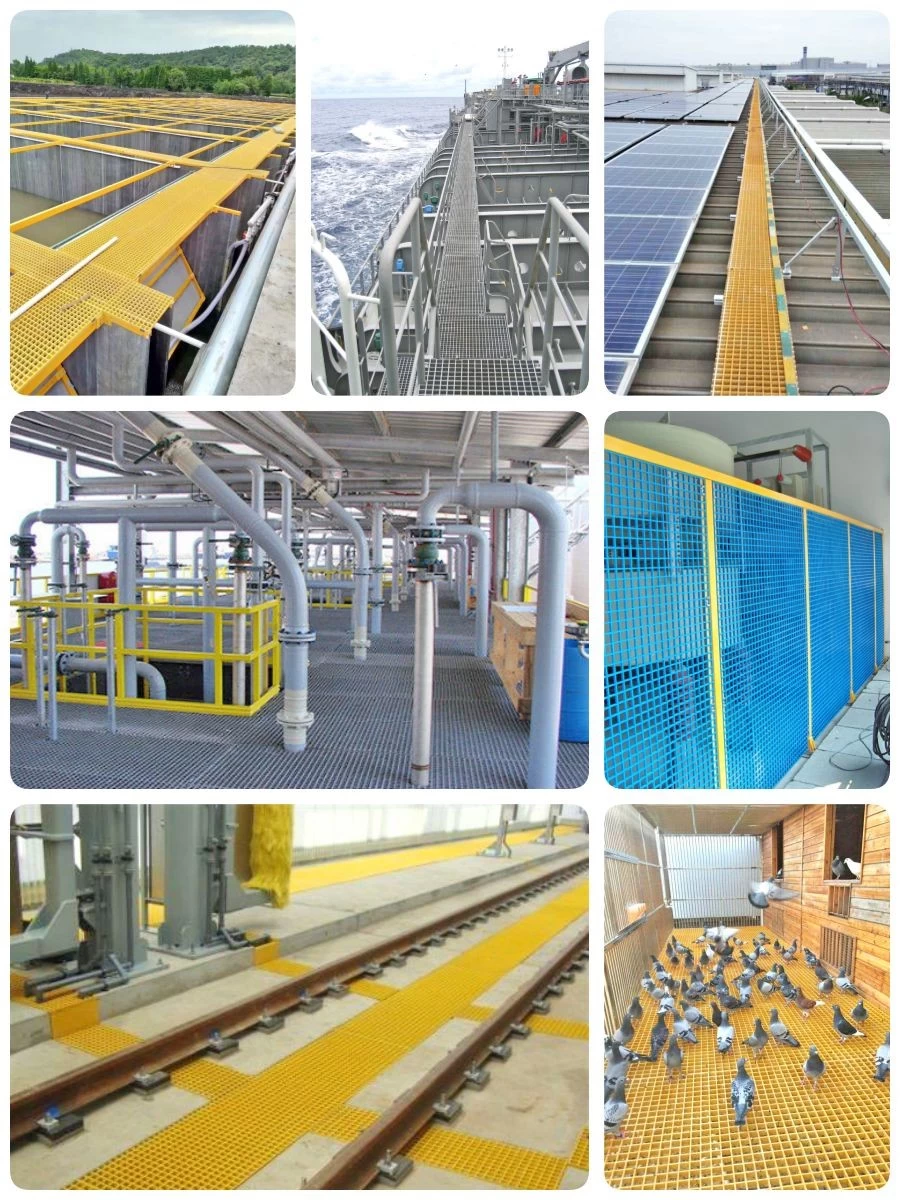

Mold FRP Grating Industries used

- Chemical plant and metal surface treatment plant

- Construction engineering, traffic and transportation.

- Petrochemical engineering, ocean survey, water treatment engineering

- Food and beverage plants

- Textile printing and dyeing, and electronic factory

Mold FRP Grating Locations used

- Anti-slip floor, stair tread, foot bridge

- Operatrion platform, trench cover

- Security and safety fence, handdrail

- Off-shore oil rig, shipyard, shipping deck

- Ramp ladder, scaffold, railway

- Decorative grid, pool floor panel

Molded Floor Walkway Open Mesh Glass Fiber Reinforced Plastic GRP Grating