- Browse Categories

- FRP Sheet

- FRP Composite Panel

- Other Composite Panel

- Pickleball Paddle & Panel

- FRP Molded Grating

- FRP Pultrusion

- Contact Us

-

Customer Service

Shenzhen Yuyi Technology Co., Ltd

Phone: +86 0755 33228547

Mobile: +86 18567663609

Email: info@frppanlesupplier.com Contact Now

- Hot Produts

- New Products

- News

-

-

Main Purpose of FRP Panels

FRP materials have been successfully used in the field of anti-corrosion for more than 80 years, such as chemical storage tanks, underground water supply and drainage pipelines, offshore cruise ships, wind power facilities, etc. Its excellent anti-corrosion and aging resistance have been widely recognized. -

What are the construction materials of rock climbing walls?

The artificially designed rock walls are more and more sought after and loved by the masses, and their construction materials are mainly divided into FRP sandwich panel, wooden board and engineering plastic. -

FRP Panels for Outer Skin of Transport Tank

In addition to being used on refrigerated trucks, FRP panels can also be used on cooling tower bottom plates, mobile homes and trailers. But few people know that the FRP flat can also be applied to the outer skin of the tank truck. -

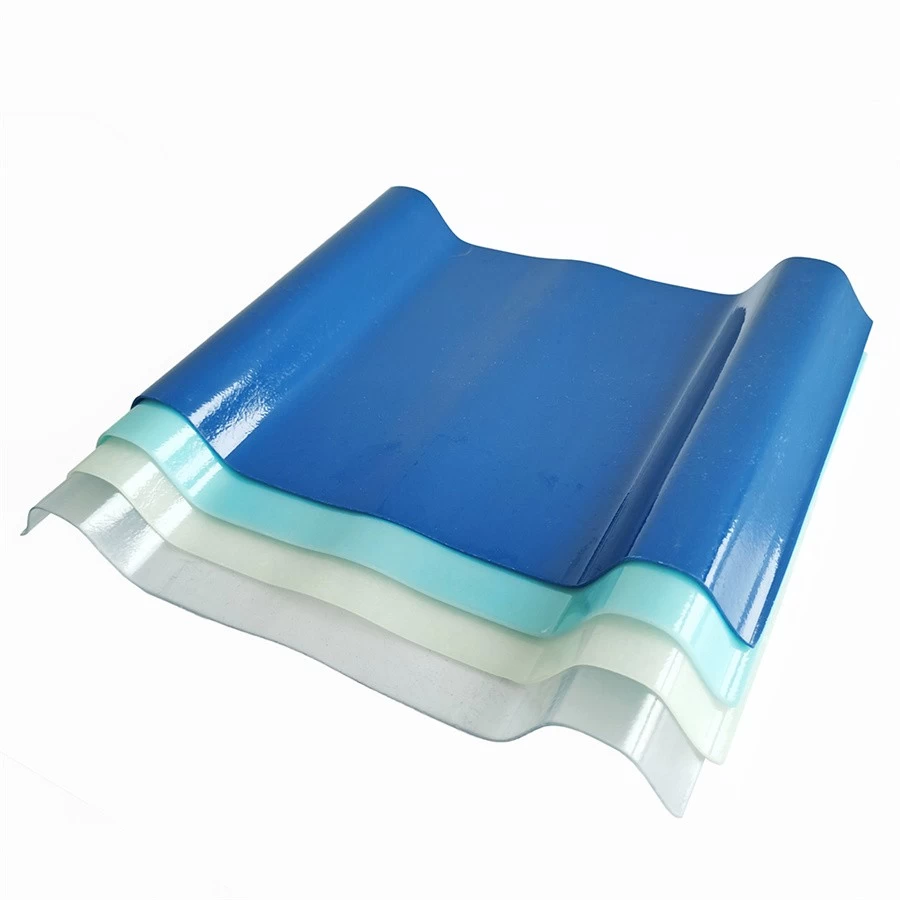

Raw Materials of Continuous Molding Process of FRP Roof Panel

FRP roof panels raw materials include: fiberglass chopped strand mat, resin matrix,Anti-aging surface layer and fillers. This article gives a brief introduction.

-

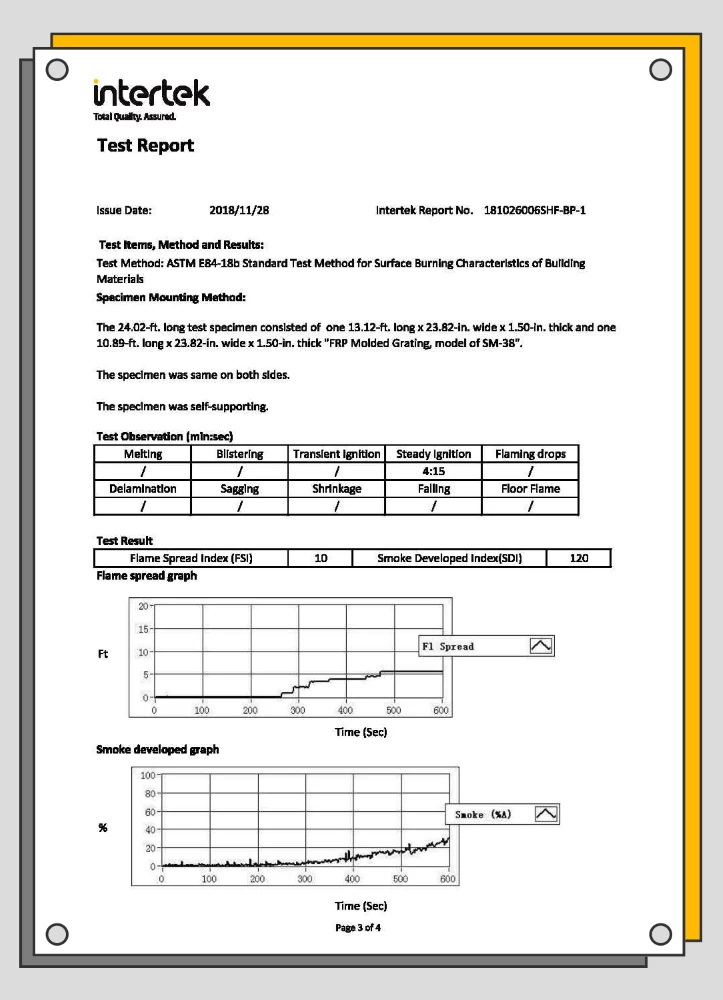

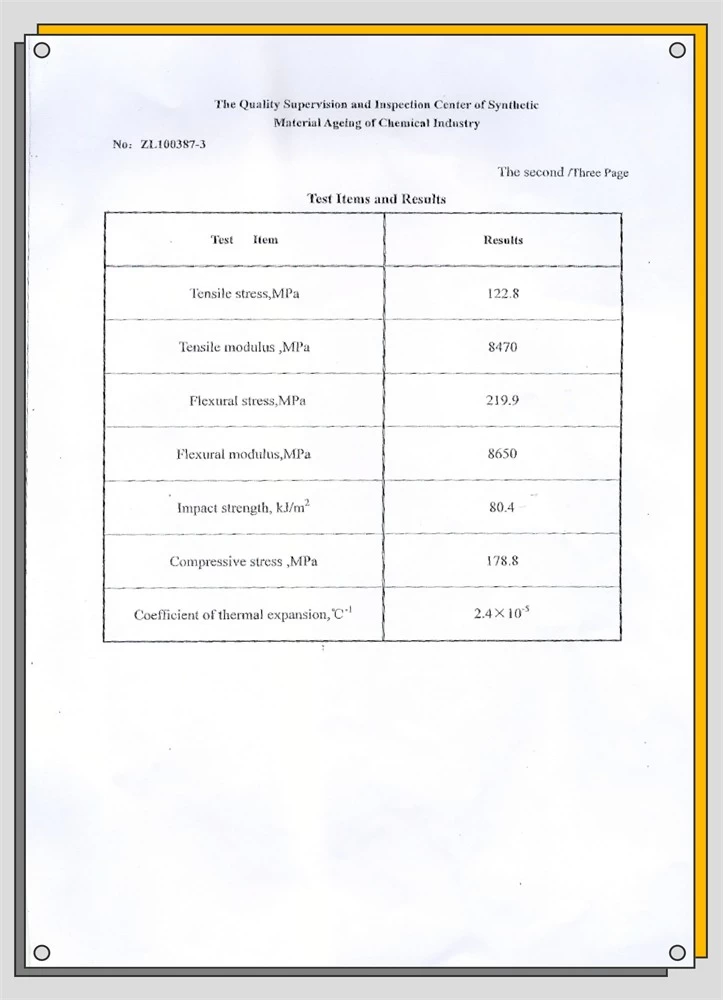

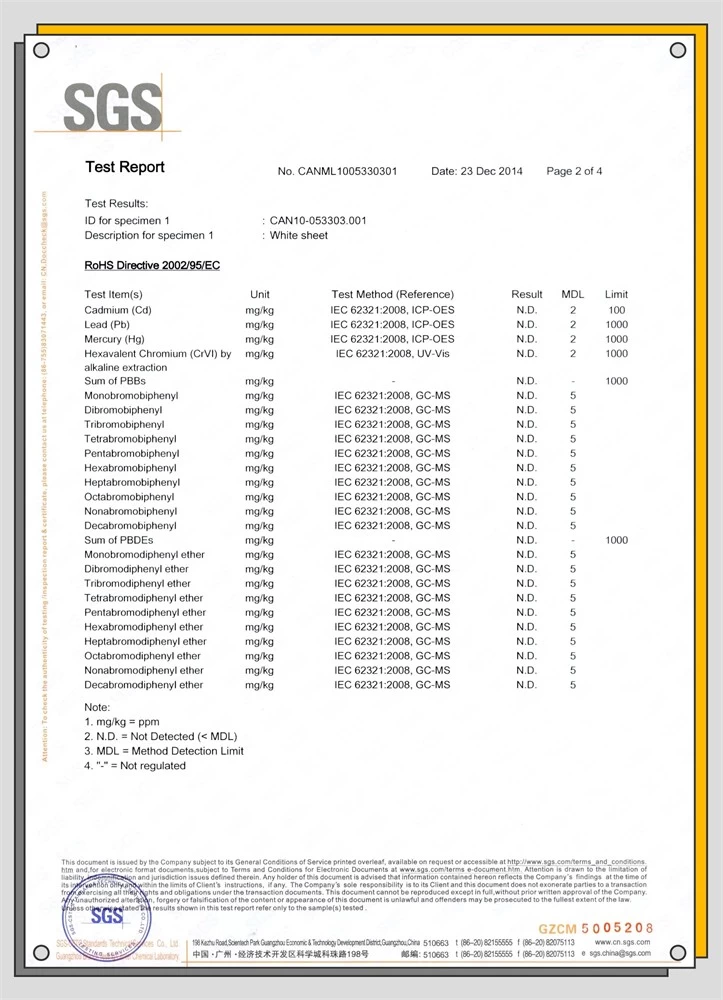

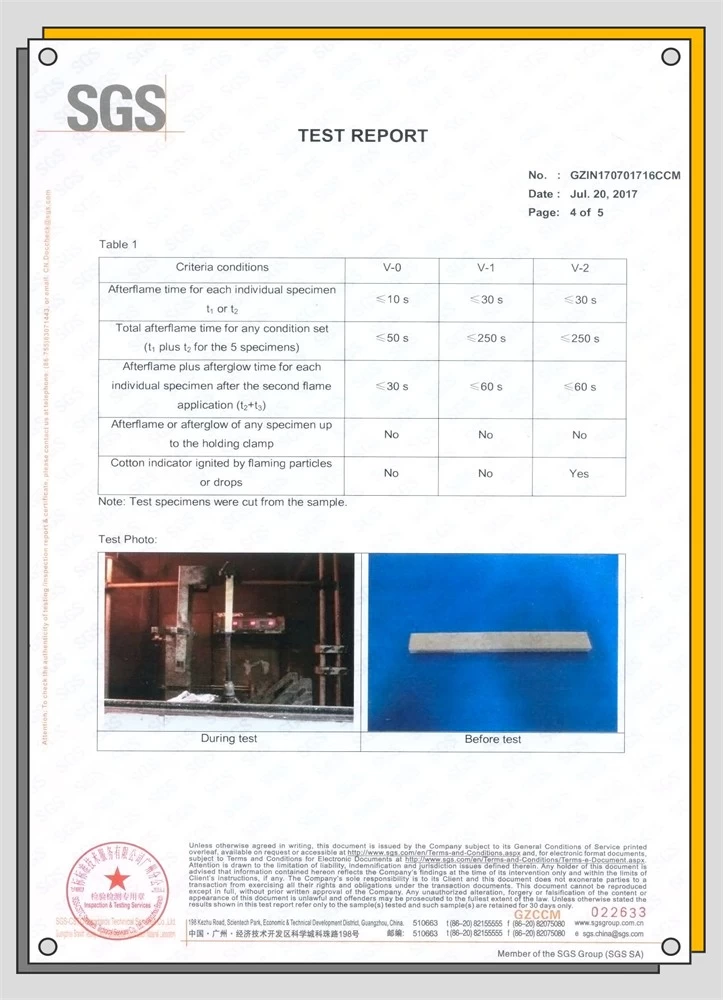

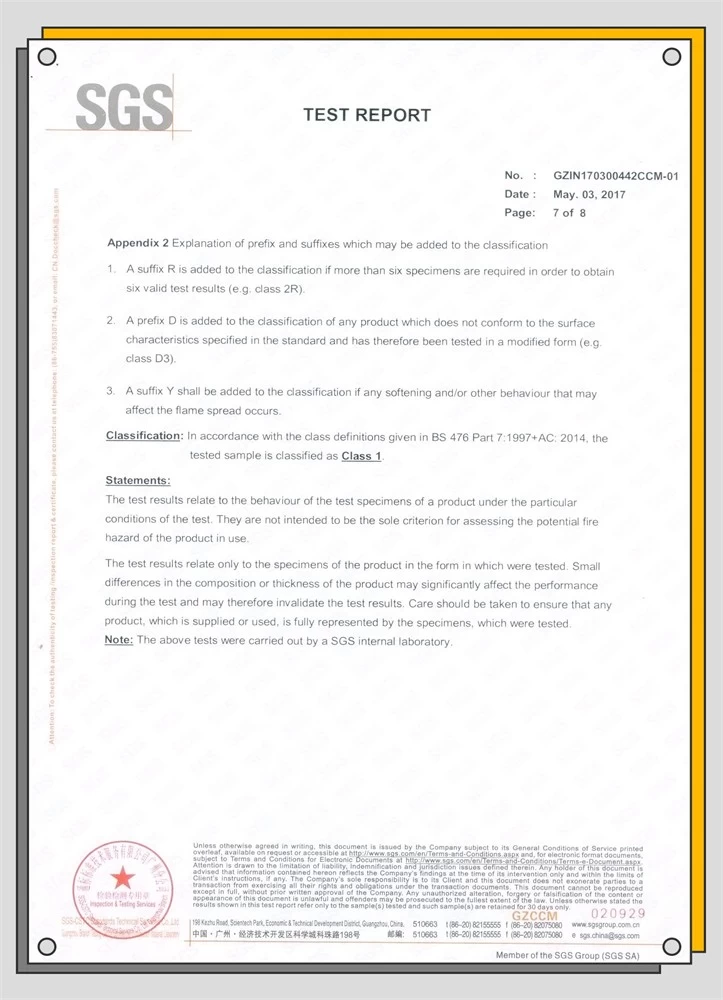

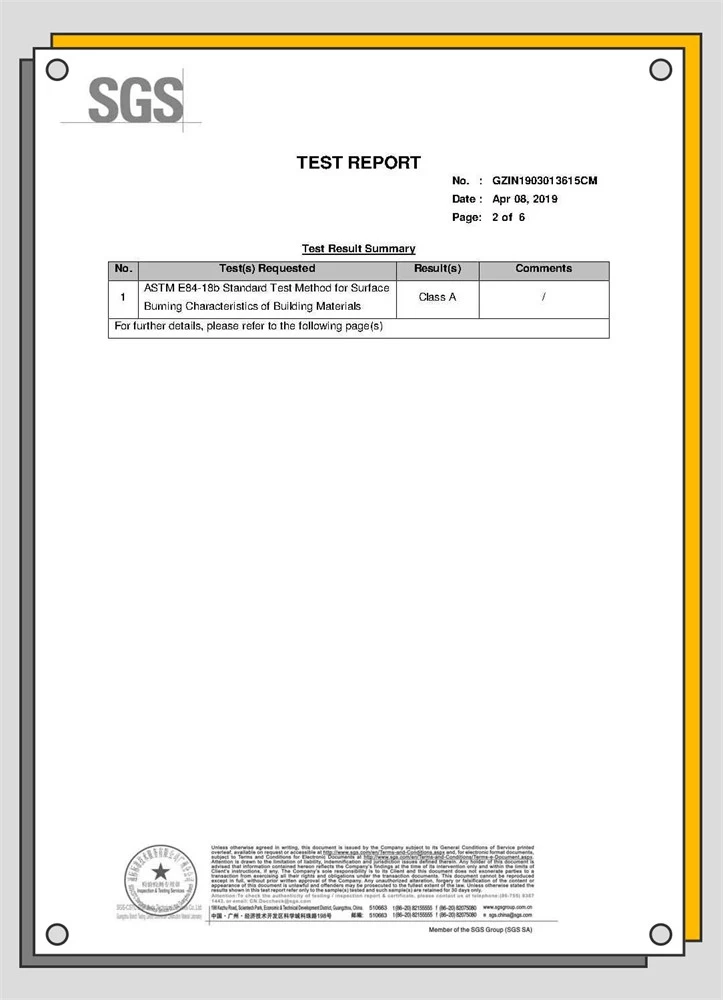

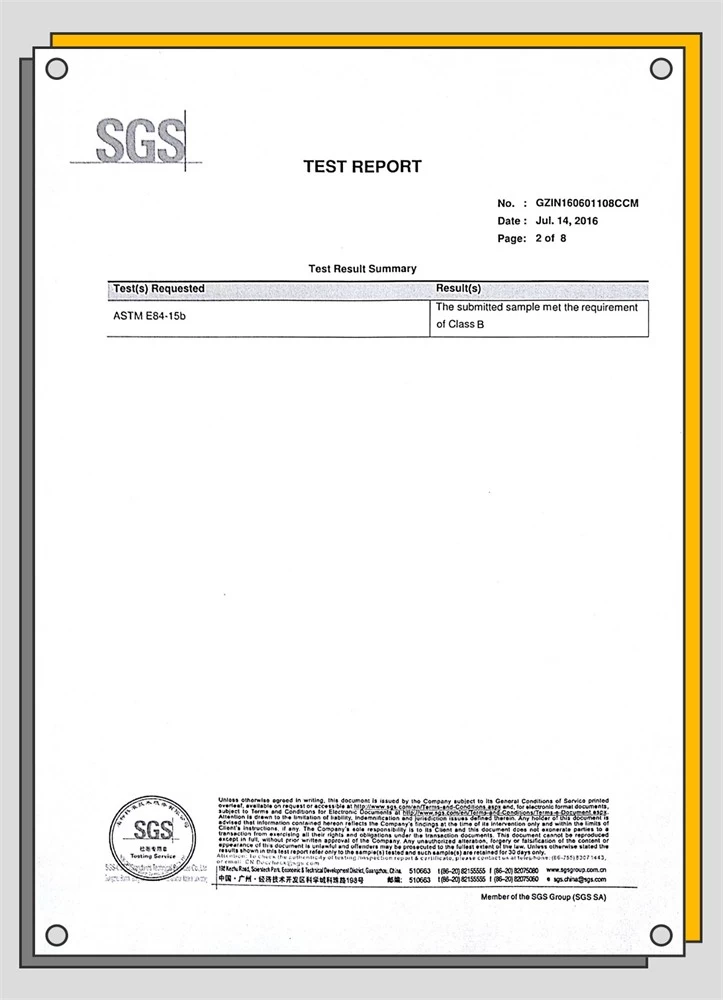

- Certifications

-

- Subscribe

-

Get email updates on new products

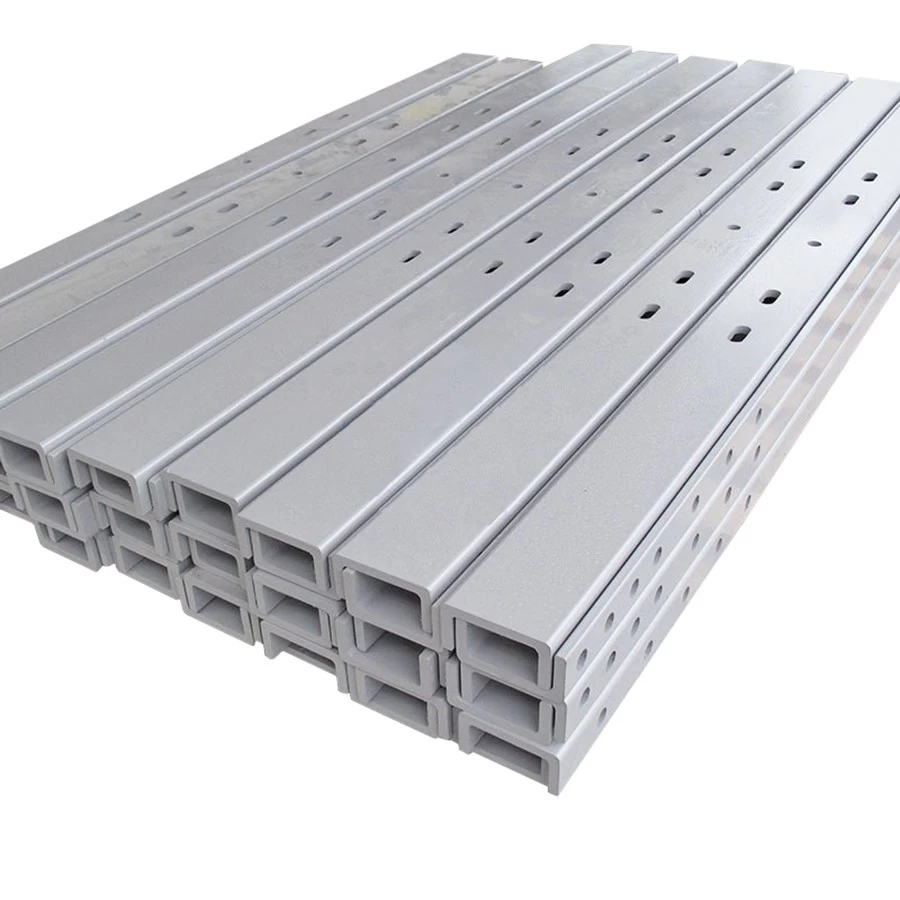

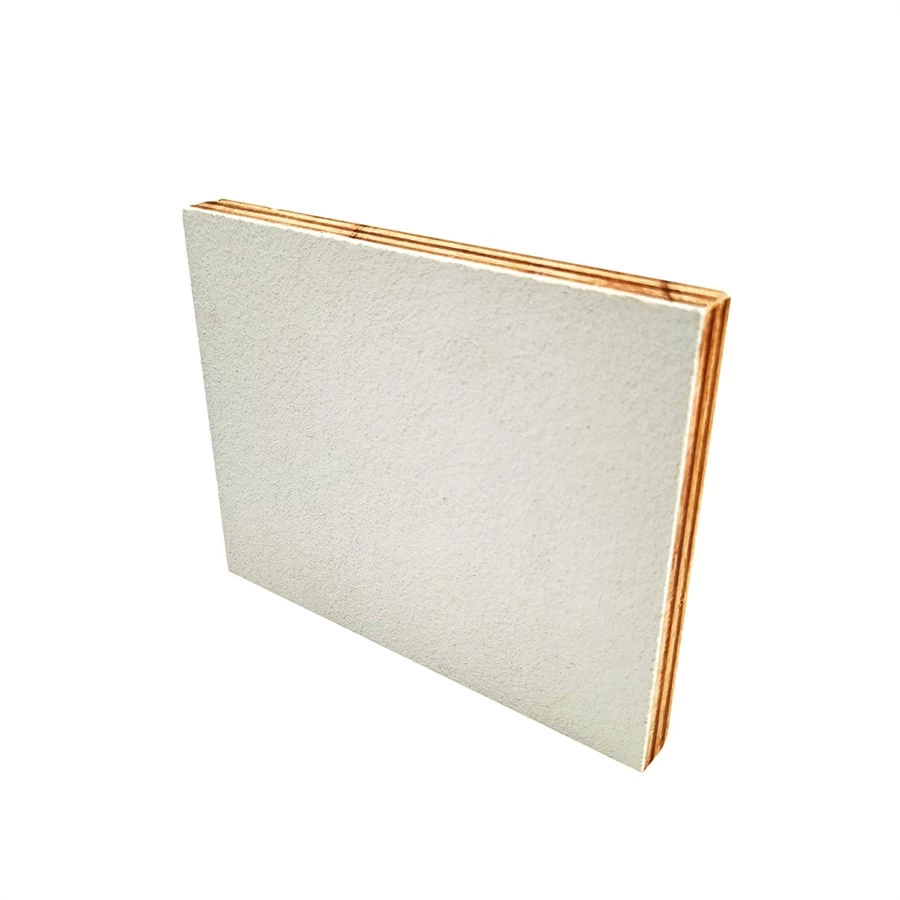

Composite Panels Fiberglass Coated Over Plywood For Camper Walls

- Outer skin material: FRP sheet

- Core material: Plywood

- Max thickness: 25mm

- Max size: 2500x5000mm

- Composite layers NO.: 2, 3, 4, 5 or customized

- Processing:Pre-embedded, Carved, Windowed, Drilled

Composite Panels Fiberglass Coated Over Plywood For Camper Walls

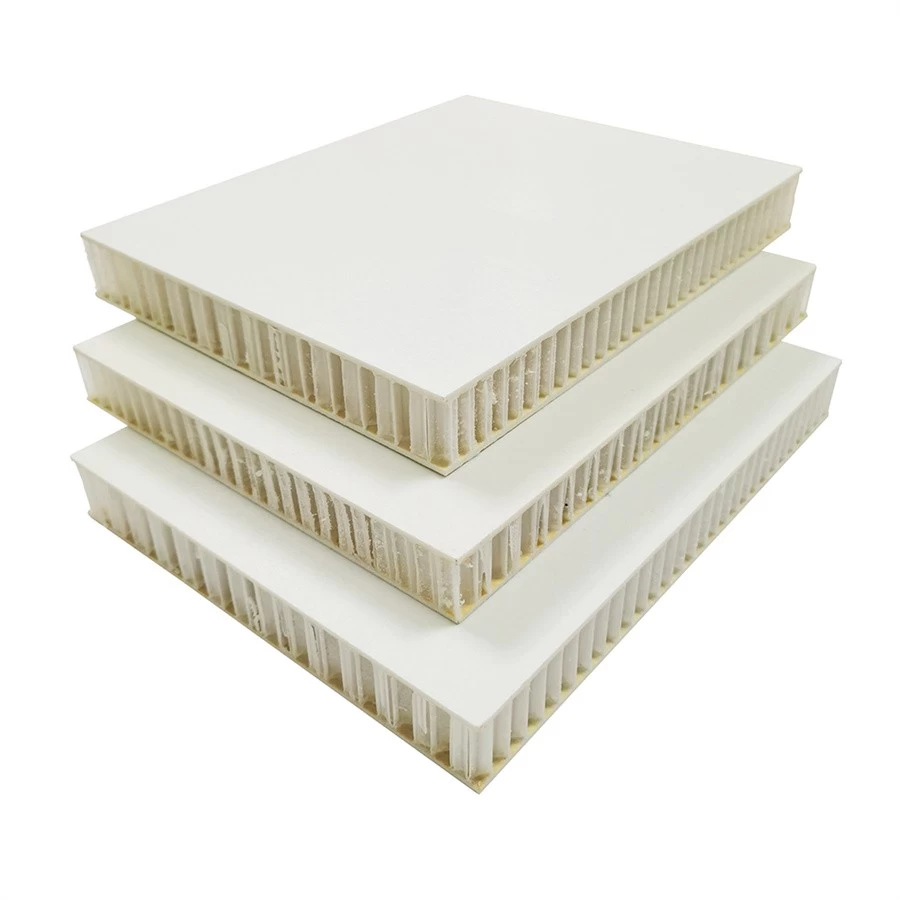

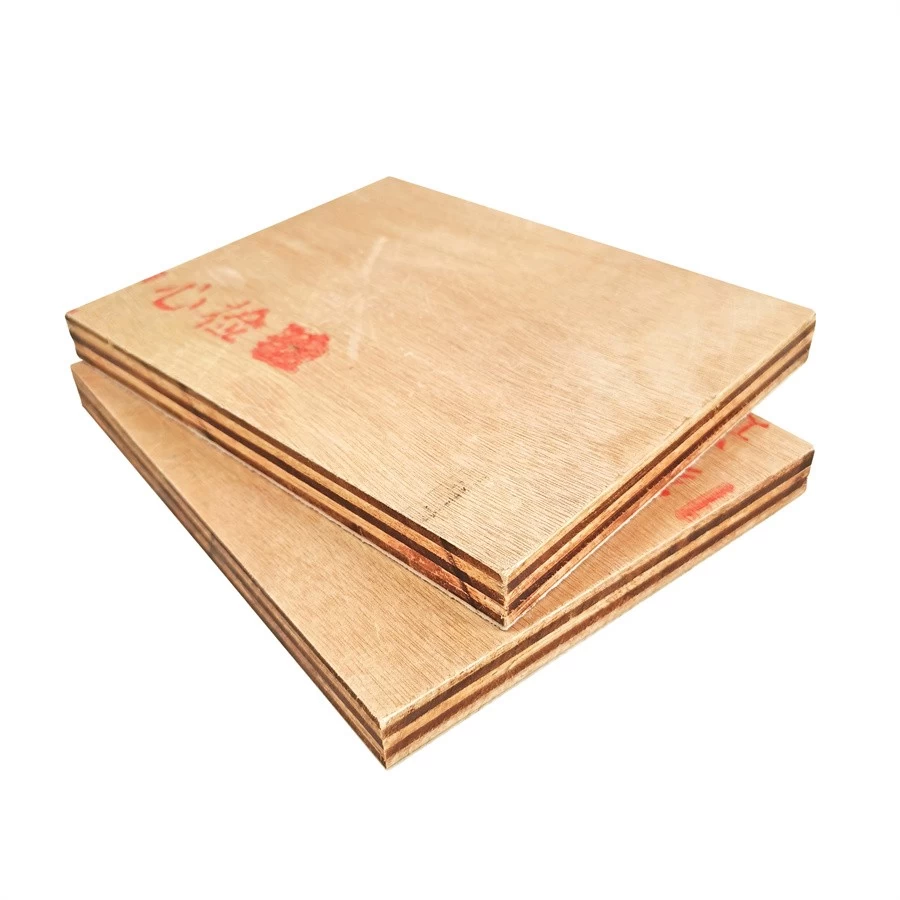

FRP Composite Panel Structure

- Outside skin: FRP Sheet

- Foam core: PU Foam, XPS, PVC Foam, EVA Foam etc

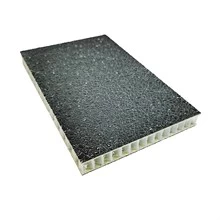

- Honeycomb core: PP Honeycomb, Aluminum Honeycomb, PP hollow etc

- Solid core: Plywood, OSB etc

- Inside skin: FRP Sheet produced by china fiberglass over plywood manufacturers

FRP Composite Panel Structure Advantages

The FRP composite panel has the characteristics of FRP sheet and core materials at the same time.

- FRP Sheet Skin: High strength and Anti-corrosion, easy clean etc

- Foam core: Temperature insulation

- Honeycomb core: Lightweight with high strenth

- Solid core: Higher strength requirements

For more composite panels details, please click china fiberglass coated plywood suppliers

FRP Composite Panels Types

|

PU Foam Core |

XPS Foam Core |

PP Honeycomb Core |

Plywood Core |

|

|

|

|

|

PVC Foam Core |

PP Hollow Core |

4 layers Panel |

5 layers Panel |

|

|

|

|

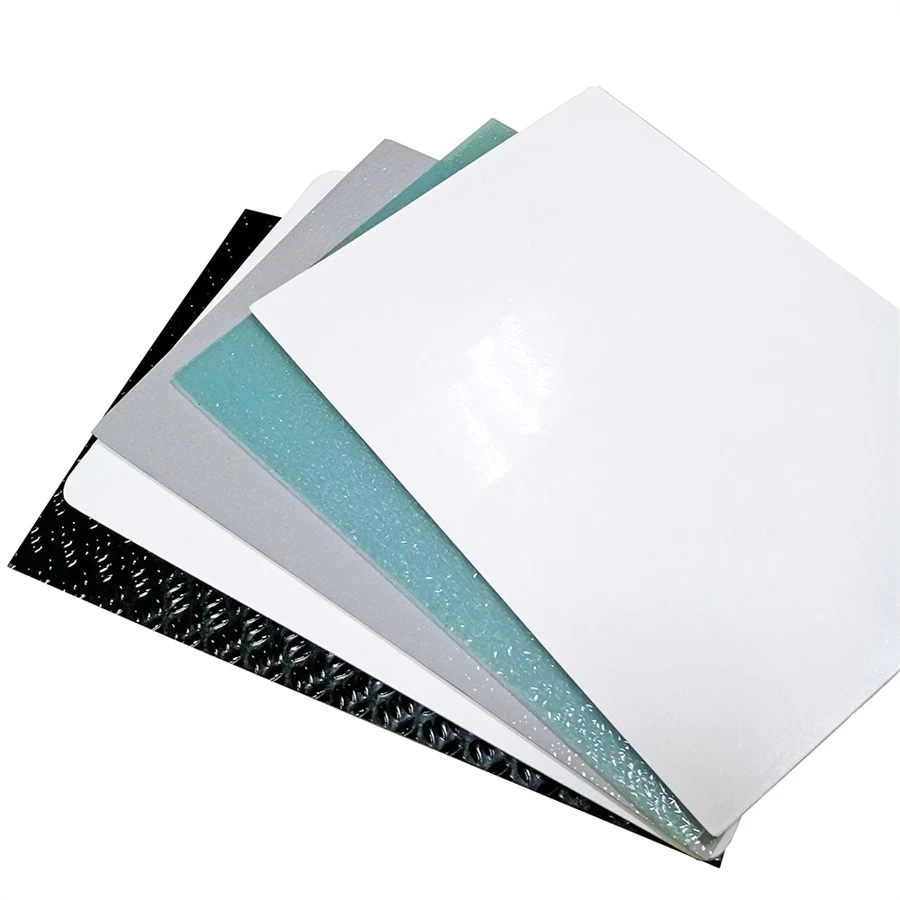

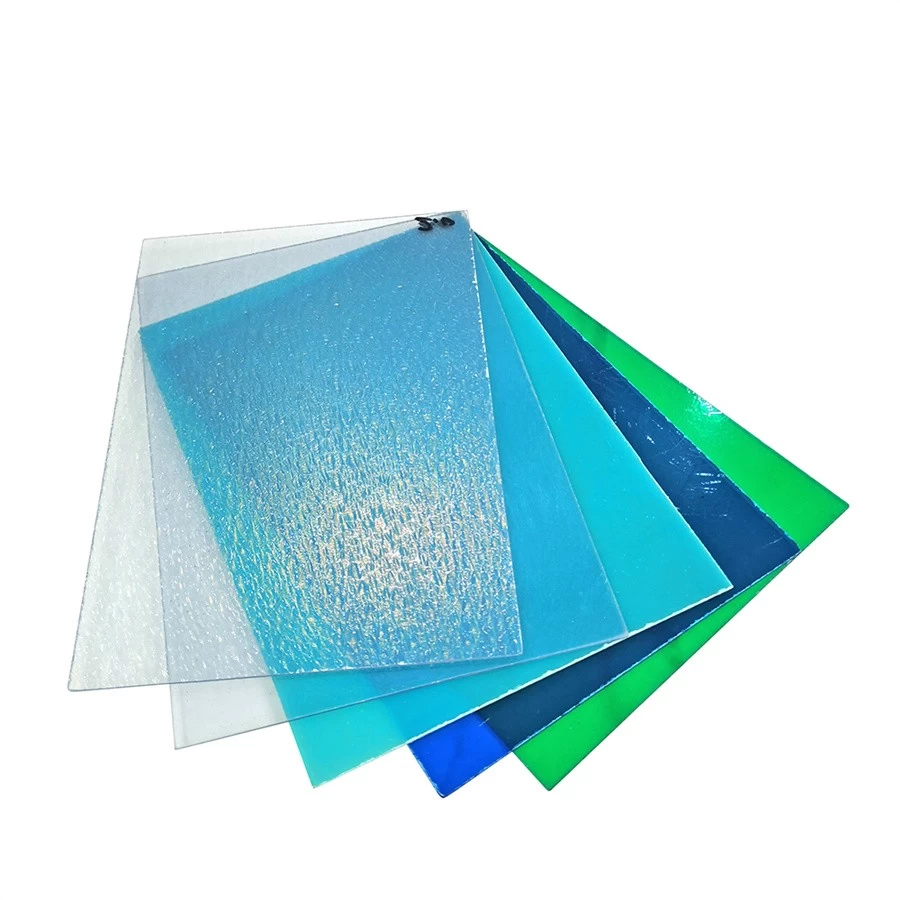

FRP Sheet Skin Surface Types

|

Without Gel-coat |

Standard |

Surface Mat |

Matte |

|

|

|

|

|

Woven Based |

Pebbled | Anti Slip | Gritted |

|

|

|

|

FRP Composite Panels Applications

The following projects comspoite panels are provided by china fiberglass covered plywood factories

Composite Panels Fiberglass Coated Over Plywood For Camper Walls