Improvement of common problems in the production of FRP composite panels

Common problems such as delamination, bulges, and pits will appear in the production process of FRP composite panels. This article will explain and improve suggestions for these problems.

|

|

1. Delamination of FRP composite panels

- The selection of adhesive is unreasonable. Before mass production, bonding and tensile tests are required to select a suitable adhesive.

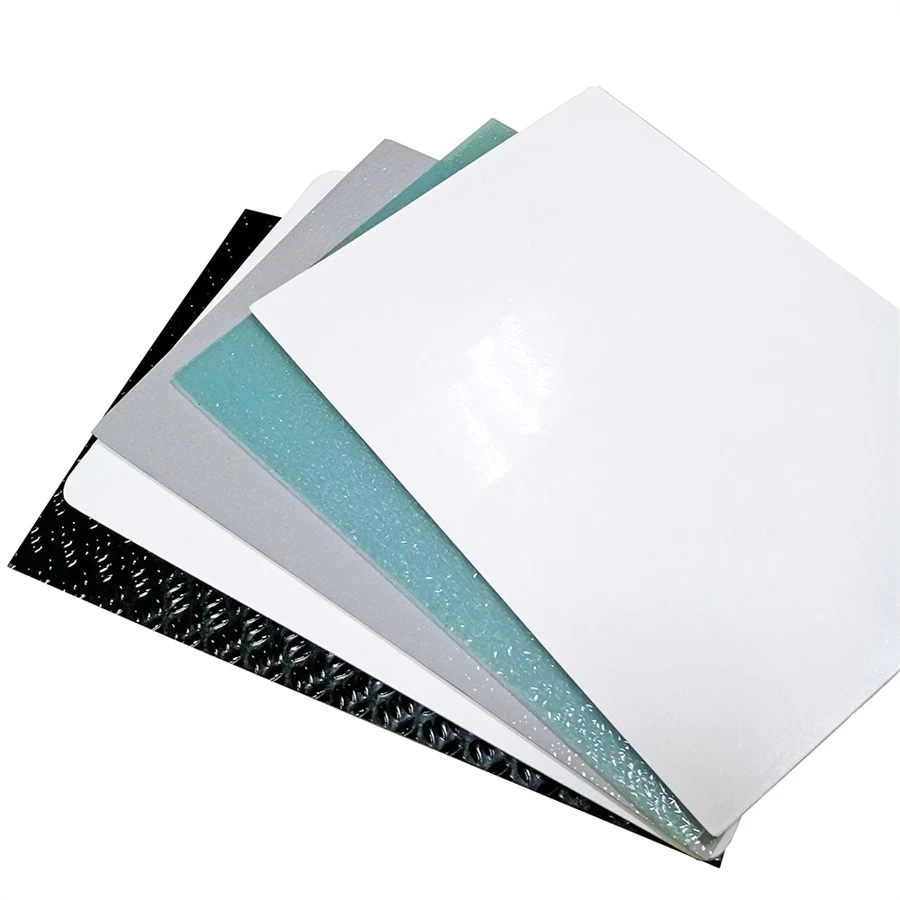

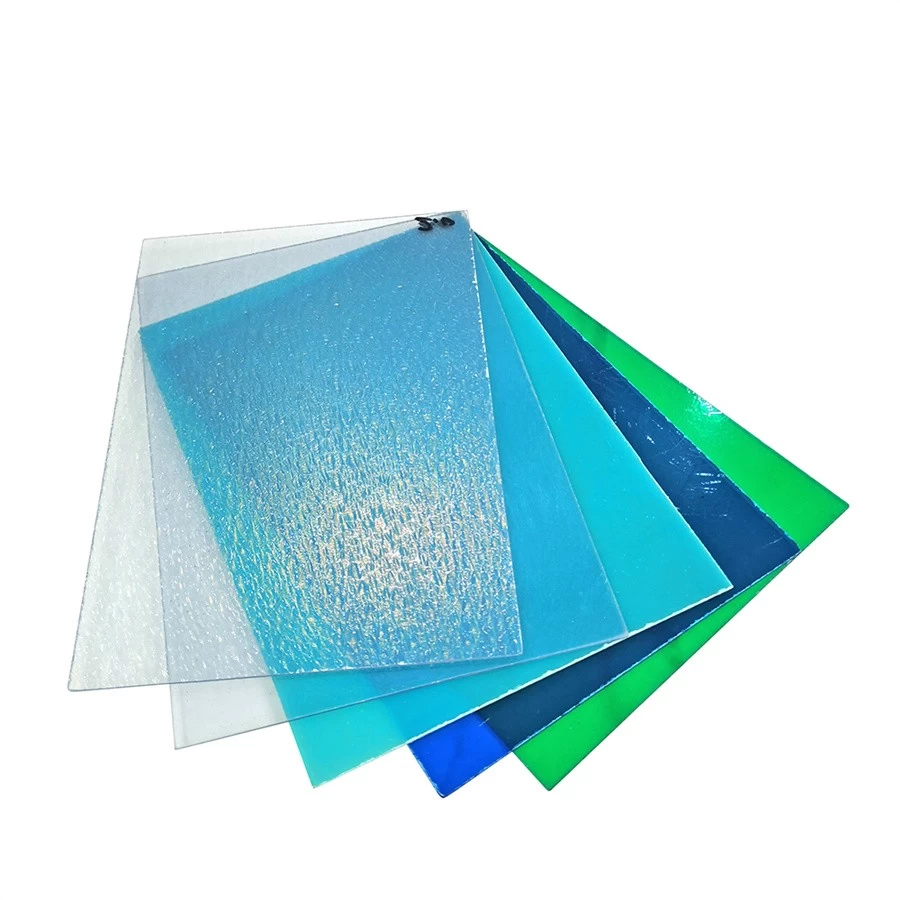

- Grease, dust, dirt, etc. on the surface of the core material layer or the surface of the FRP Flat Sheet. Carefully clean the surface of each layer of material before lamination.

- The film on the back of the FRP panel has not been removed, and the production of the Yuyi Tech FRP panel is strictly controlled to ensure that there will be no residual film on the back.

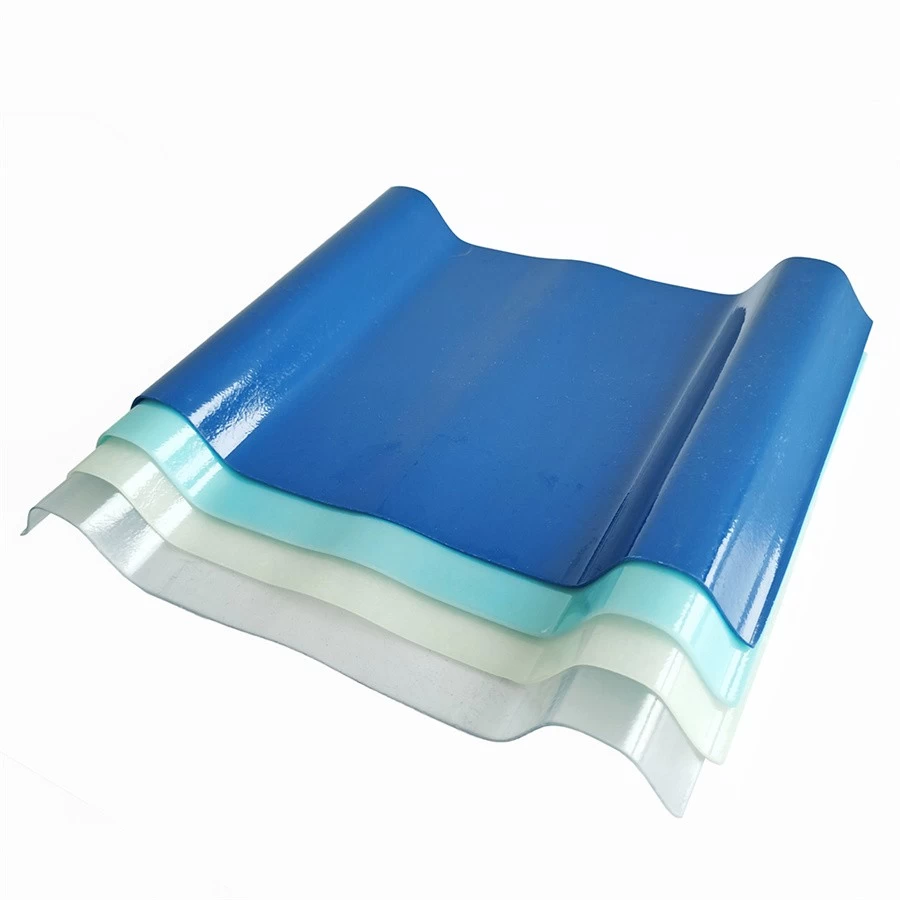

2. The surface is bulging (which is one of the most frequent problems of FRP composite panels when the bulging phenomenon occurs)

- The glue squeegee is uneven. It is necessary to formulate technical operation specifications and timely inspect and verify them.

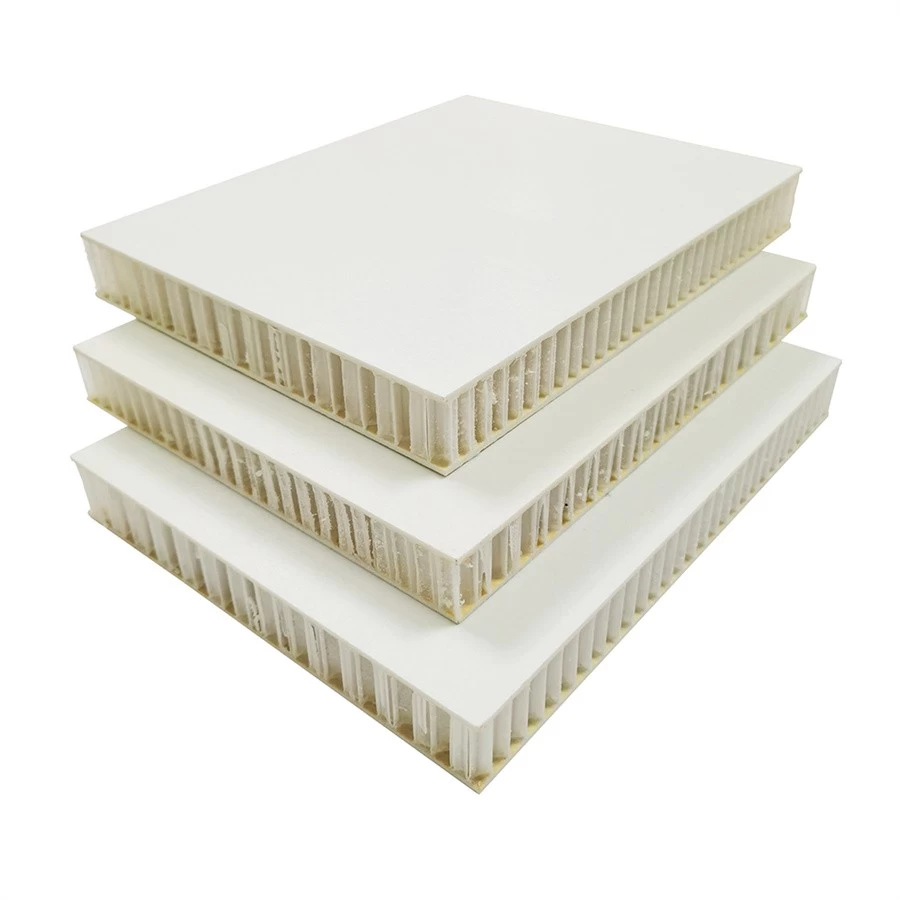

- The core material and FRP Sheet are not flat, or the pressure is too small, the adhesive cannot fully bond with the surface of each layer to be bonded.

- There are quality problems in the core material or the FRP plate itself (such as delamination of the wood plywood itself, etc.). Check the raw materials of incoming goods.

3. Surface pits

- 1. There are large dust particles or dirt on the upper and lower surfaces of the mold table.

- 2. There are large dust particles or dirt on the surface of the FRP plate.

- 3. There are defects in the core material or the FRP Sheet (such as dents, defects, etc.).

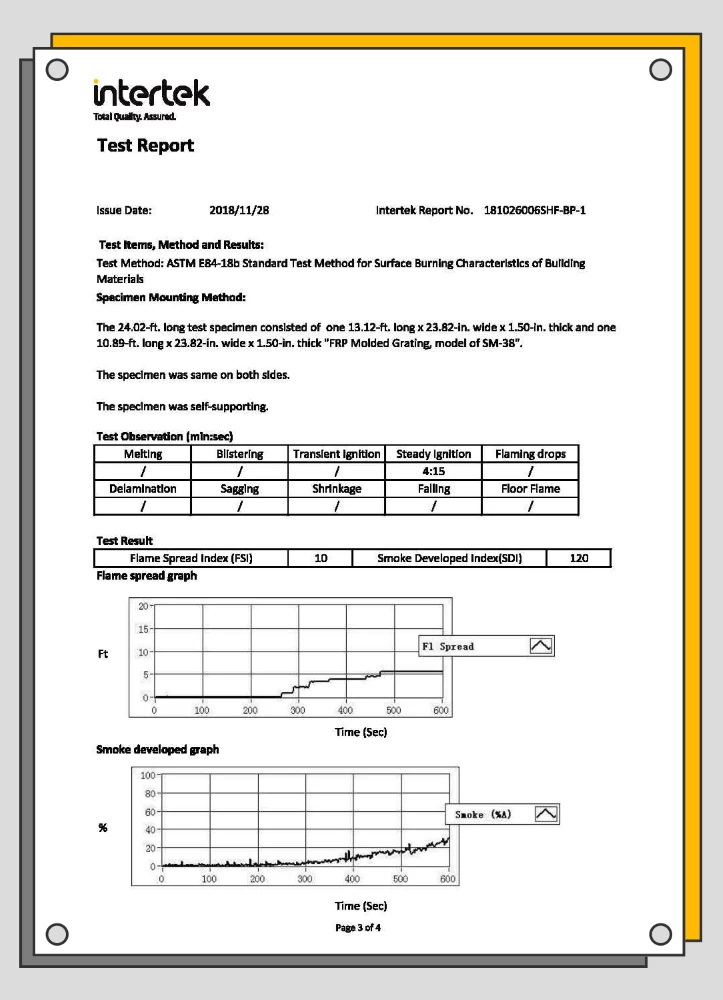

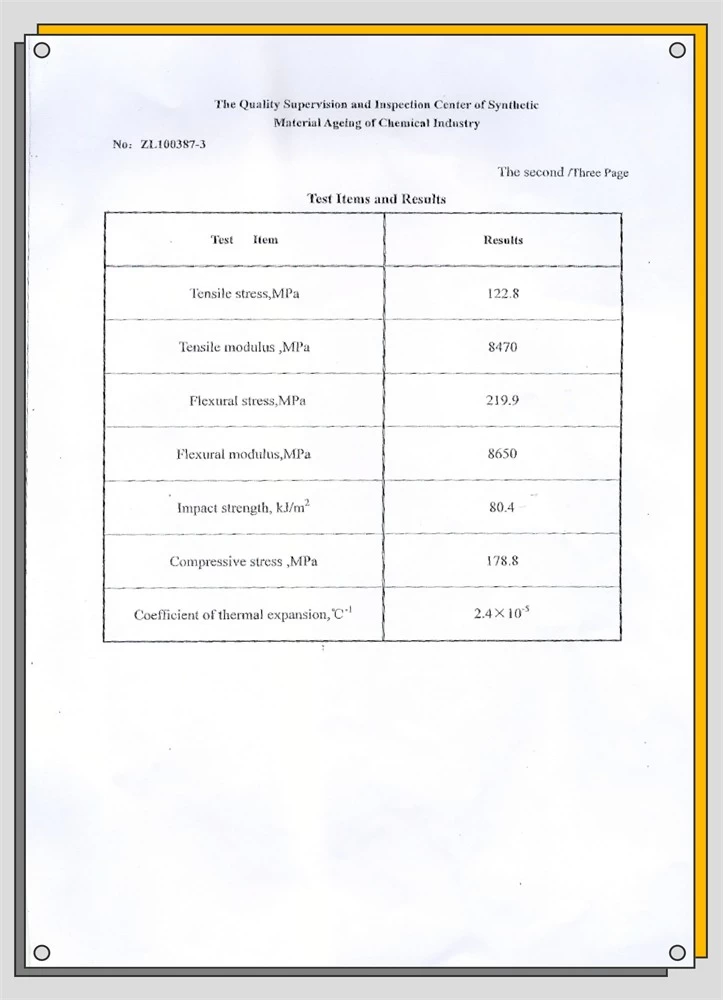

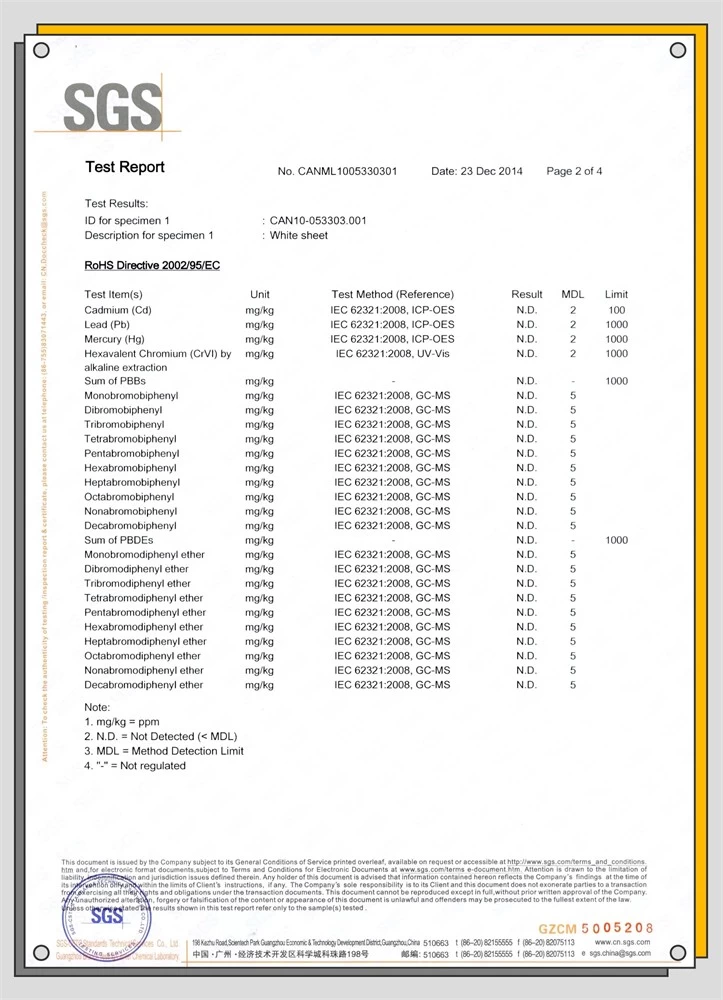

Every product of Shenzhen Yuyi Technology Co., Ltd. must go through strict quality control, from raw material selection, process control, pre-shipment quality inspection and other processes to protect the rights and interests of customers, in order to provide each customer with the best High-quality and safe products bring customers solutions with higher added value.

If you need more information and industry news of China FRP panels Suppliers, please follow us or contact our customer service staff.