FRP Composite Panels For Refrigerated Trucks

Refrigerated trucks are usually used to transport meat, seafood, fruits and vegetables, ice cream, etc. that need to be refrigerated or kept fresh. In order to ensure that the goods can keep low temperature and fresh during transportation, the compartment panels of refrigerated trucks play a very important role. So, what kind of characteristics do refrigerated truck compartment panels need to have? What kind of material can be used to make refrigerated truck compartment panels?

- After the cold machine of the refrigerated truck is started, the temperature inside the compartment panel must be kept within a certain range, so the compartment panel of the refrigerated truck must be kept insulated.

- The weight of the transport vehicle will be controlled, so in order to load more goods, the weight of the carriage must be light, which is convenient for installation and maintenance.

- During the transportation, accidents may occur at any time, so the quality of the carriage panels used to make the carriages should be good and have a certain impact resistance.

|

|

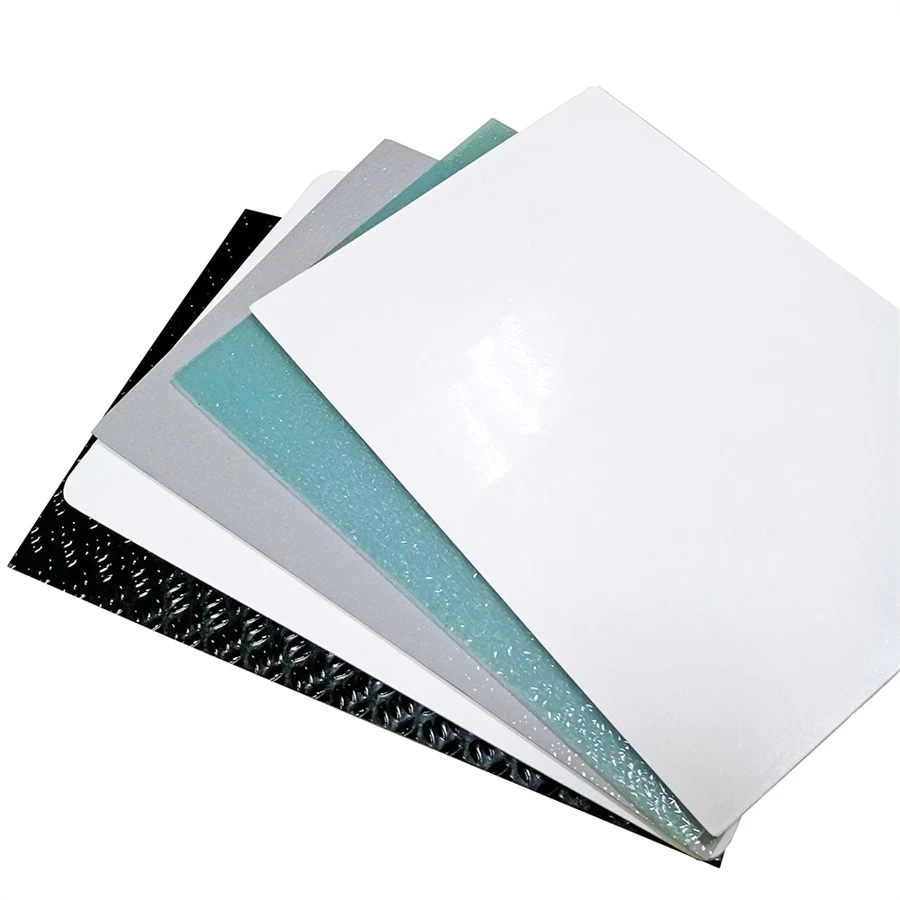

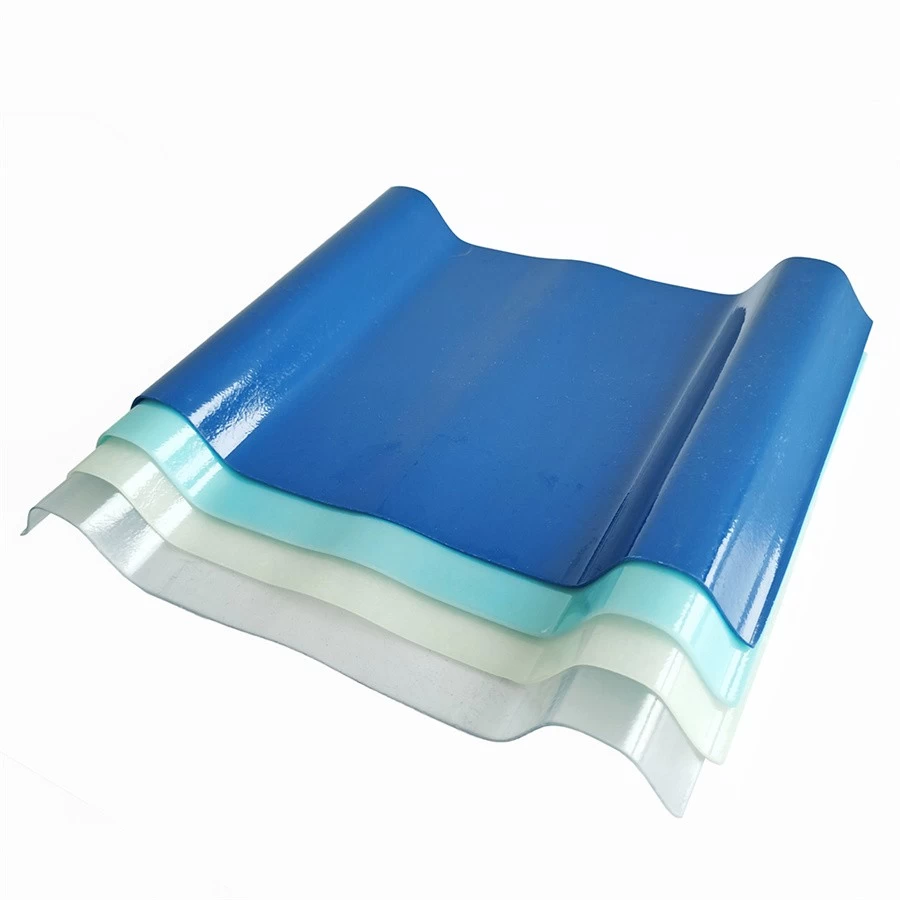

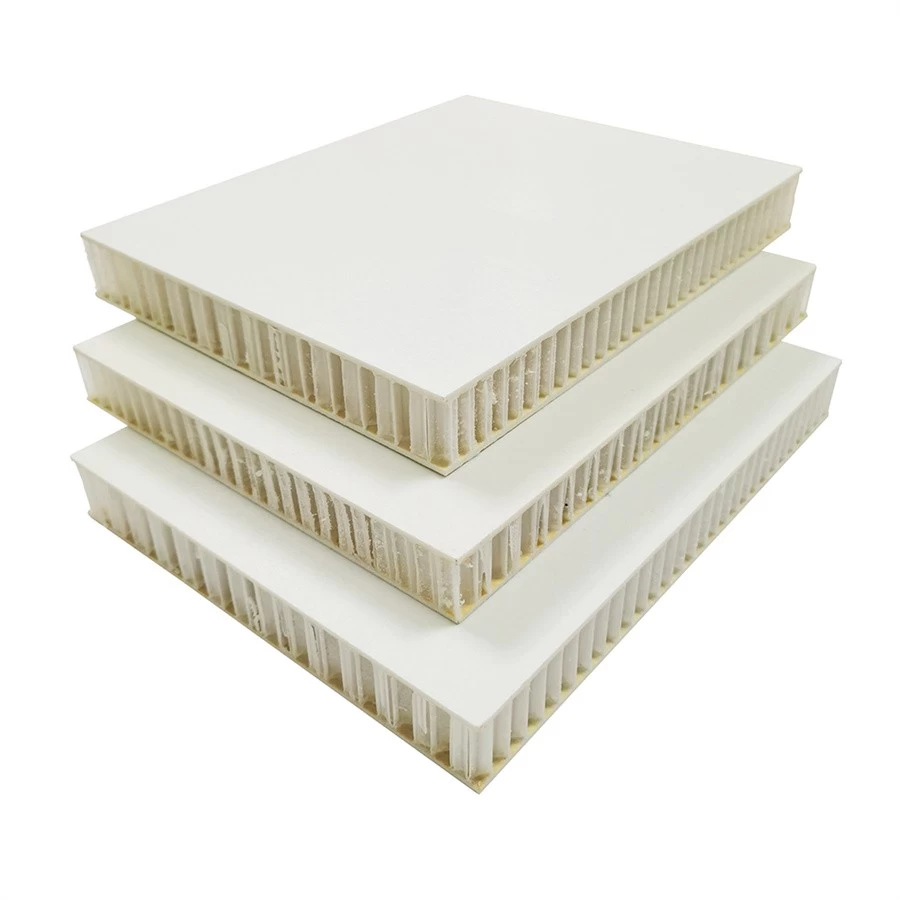

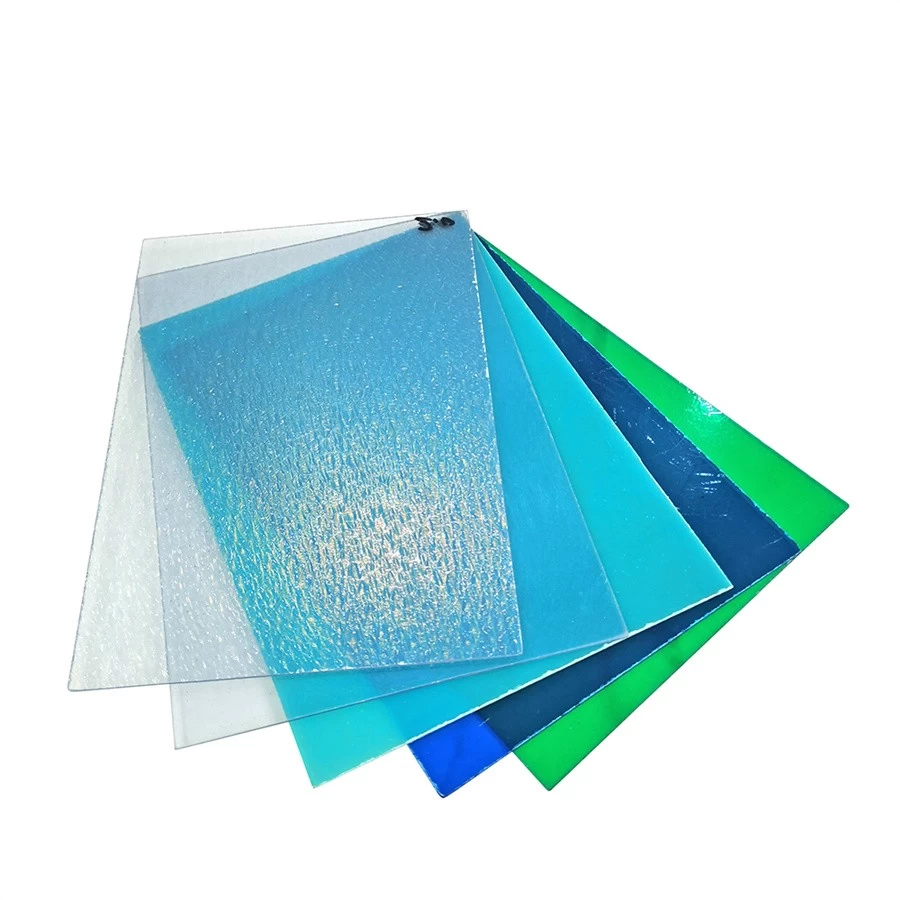

| FRP PU Panel | FRP XPS Panel |

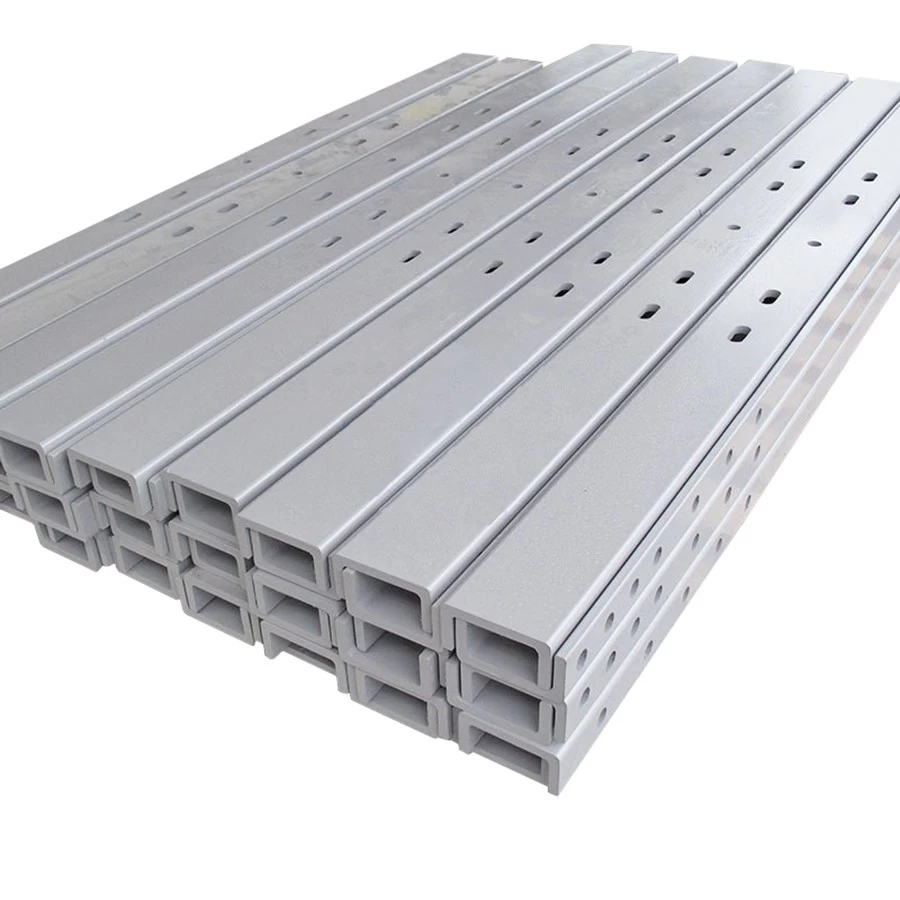

Therefore, the refrigerated truck compartment panel should have the characteristics of thermal insulation, light weight, strong hardness, impact resistance, convenient installation, and long service life. Yuyi Tech recommends FRP XPS composite panels and FRP PU composite panels for the production of refrigerated truck compartment panels. FRP XPS sandwich panel is light in weight, strong in impact resistance, cost-effective, and has thermal insulation effect; while FRP PU composite board has low thermal conductivity and better thermal insulation performance. FRP composite panels with a thickness of 80mm can usually be used to make refrigerated truck compartment panels.